PET Diffusion Film

Transparent PVC Film

Description

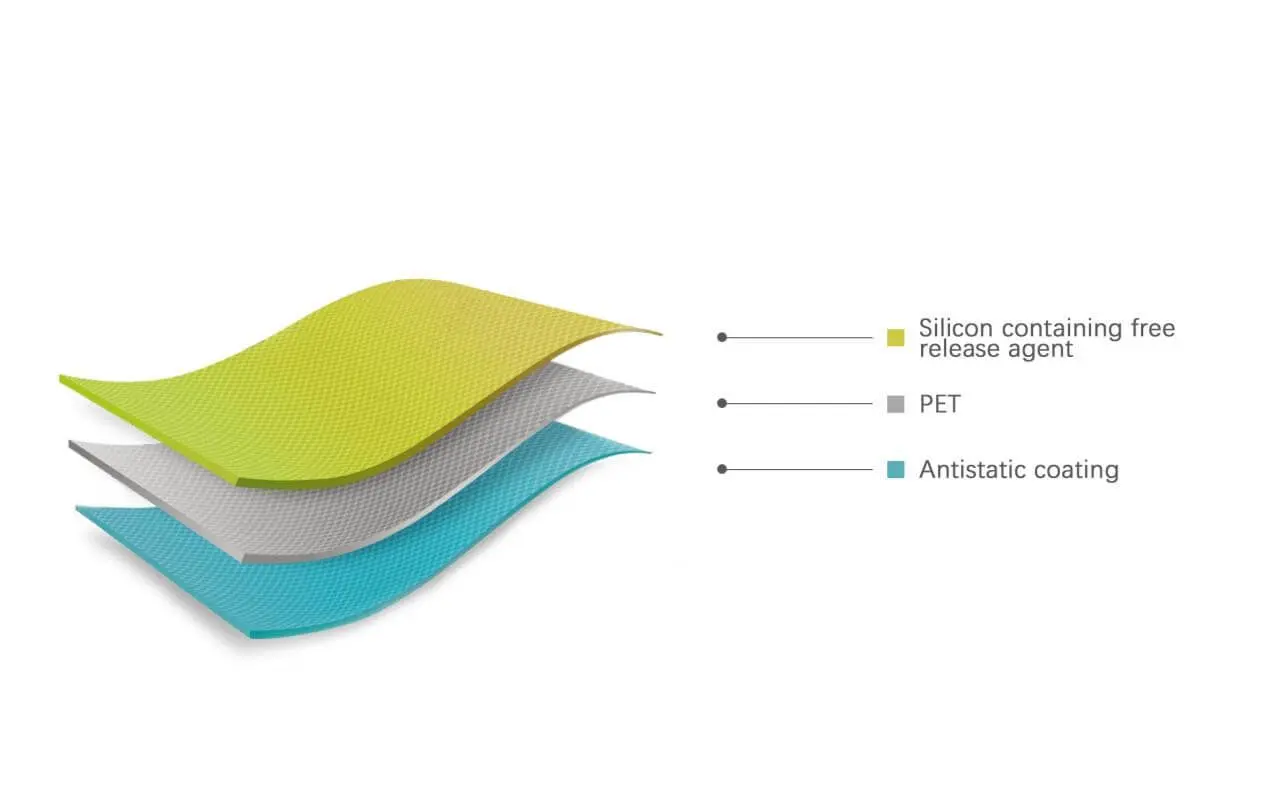

Release film refers to a film with differentiated film surface. The release film is not sticky or slightly sticky after contact with specific materials under limited conditions. The release film is a silicone release agent that is coated on the surface of environmentally friendly PET, PE, and OPP films, allowing it to exhibit extremely light and stable release force against various organic pressure-sensitive adhesives.

Different organic pressure-sensitive adhesives, such as hot-melt adhesives , acrylic adhesives, and rubber-based pressure-sensitive adhesives, etc., require different release film release forces. For isolation products, the adhesive viscosity is different, and the release forces correspond to each other. Adjust to achieve extremely light and stable release force during peeling.

Features

- The release film has corrosion resistance, excellent electrical insulation (especially high-frequency insulation), can be chlorinated, irradiated and modified, and can be reinforced with glass fiber. The melting point, rigidity, hardness and strength of low-pressure polyethylene are high, and it is water absorbent. Small, with good electrical properties and radiation resistance high-pressure polyethylene has good softness, elongation, impact strength and permeability ultra-high molecular weight polyethylene has high impact strength, fatigue resistance and wear resistance, and low-pressure polyethylene is suitable It is suitable for making corrosion-resistant parts and insulating parts high-voltage polyethylene is suitable for making films, etc. ultra-high molecular weight polyethylene is suitable for making shock-absorbing, wear-resistant and transmission parts.

- The release film is moisture-proof and temperature-resistant. Silicone oil has a certain degree of temperature resistance, and the specific temperature resistance varies depending on the use of the product and the use of domestic and imported silicone oil. Generally, it can withstand up to about 150 degrees.

Classification Of Release Films:

- Release films can be divided into PE release films based on different base materials PET release films, OPP release films, composite release films (that is, the base material is composed of two or more materials), etc.

- According to the release force, it can be divided into light release film, medium release film and heavy release film.

- According to color, it can be divided into PET release films of various colors such as red release film, yellow release film, green release film, blue release film, etc.

- According to surface treatment, it can be divided into single-sided release film, double-sided release film, silicone-free release film, fluoroplastic release film, single-sided corona, double-sided corona, frosted release film, and matte release film. membrane etc.

Single Sided Release Film

HDPE (low-pressure polyethylene) release film LDPE (high-pressure polyethylene) release film used for sealing tapes and other waterproof membranes mechanical product packaging, hot melt adhesive packaging, health care products (diapers), anti-corrosion rolls BOPP (stretched polypropylene) release film for materials such as PET (stretched polyester) release film for sealing tape, silent tape, etc. double-sided release film for adhesive protection red and green polyolefin (PE) .

Double Sided Release Film

Transparent PET double-sided release film for foam tape double-sided tape sun-resistant isolation film (HDPE silver-coated film) enhanced aluminized base material BOPP enhanced (BOPET) for waterproofing membranes for sun protection and cooling.

Application

It is widely used in the processing of various products, such as electronic power and IT display screens. Mobile phones, LCD and PDA, medical, home appliance manufacturing, anti-counterfeiting materials, semiconductors, automobiles, nameplates, ceramic sheet manufacturing, tape production and die-cutting industries.

Technical Data Sheet

| Typical physical properties | |||

| Properties | Value | Unit | Test method |

| Physical properties | |||

| Proportion | 1.4 | g/cm³ | ASTM D792 |

| Optical properties | |||

| Transmittance | >88 | % | |

| Haze | <2.5 | % | ASTM D1003 |

| Mechanical behavior | |||

| Tensile strength (TD) | 182 | Mpa | ASTM D882 |

| (MD) | 181 | Mpa | ASTM D882 |

| Elongation at break (TD) | 180 | % | ASTM D882 |

| (MD) | 180 | % | ASTM D882 |

| Thermal properties | |||

| Molding shrinkage (TD) | 1.5 | % | ASTM D1204 |

| (MD) | 0 | % | ASTM D1204 |

| Release force | 18-23 | g/inch | GB/T 25256-2010 |

| Note: This test is for reference only and is not an absolute application indicator. | |||