Acrylic Film Vacuum Forming

Optical Polyester film

Description

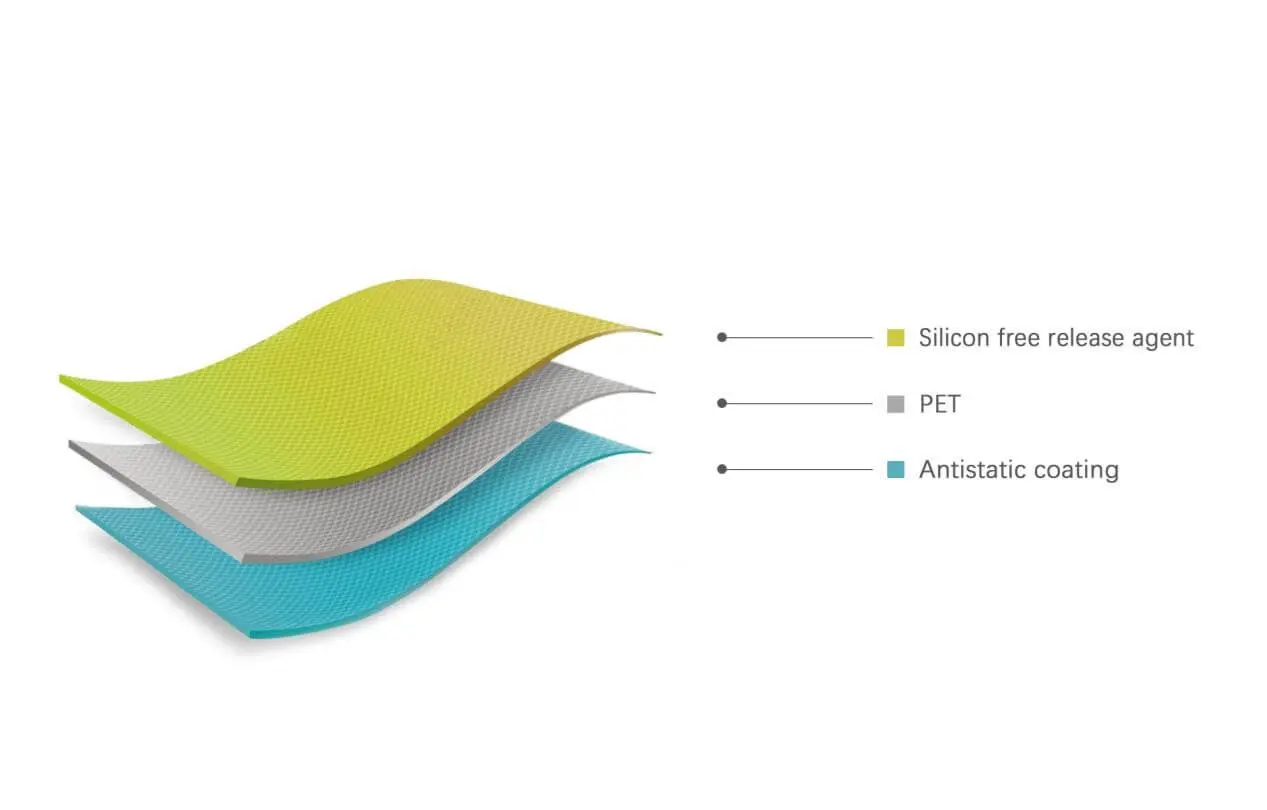

Silicone-free release film is a special release film that is different from ordinary silicone release films. Its surface coating layer is not a commonly used siloxane component, but a silicon-free fluoride coated on the PET film. Surface to achieve the effect of release.

It is a high-performance environmentally friendly release film. The base material is made of modified high-temperature-resistant polyester film. After formula optimization, lubricating materials are added to the raw materials to form the film. This silicone-free release film has certain peeling properties during the high-temperature and high-pressure lamination process. Similar to the TPX material, the surface of the silicon-free release film is not coated with any release substances that are likely to cause residue. It completely relies on the release ability of the film itself to peel off the soft board, so it will not pollute the FPC board surface and is environmentally friendly and residue-free, with strong temperature resistance, good mechanical strength and high dimensional stability, it is widely used in printed circuit boards, FPC flexible circuit boards, electronics and electrical, printing and packaging, pharmaceuticals, tape adhesion and other fields.

Features

- There is no transfer, eliminating the risk of the silicone resin release film migrating to the material it is adjacent to.

- The error value of the net weight per unit area of the coating on one or both sides of the release film is very small.

- The base film has excellent impact toughness and organic chemical properties.

- It has high reliability under extreme temperatures. The heat resistance can reach about 130℃ for a long time and can reach about 180℃ within an hour.

- Longer storage period.

The Differences Between Three Types Of Release Films:

According to different surface treatment methods, release films are mainly divided into fluorine release films, silicon-containing release films and silicon-free release films.

The main differences between the three are as follows:

In terms of price: the most expensive is the fluoroplastic release film. The price per square meter is much higher than that of ordinary process protective films, so the fluoroplastic release film is usually used for some protective films that have to use fluoroplastic release film. Material. Then the non-silicon release film, the cheapest one is the silicone oil release film.

Applications: Silicone oil release films are mainly used for some silicone-free glues, fluoroplastic release films are mainly used for high-viscosity protective films, and non-silicon release films are mainly used for silicone protective films.

Release Force:The release force of silicone oil release film and fluoroplastic release film can be very low, and the minimum release force of silicone-containing and fluorine-containing release films can be less than 5g, so they are suitable for high-viscosity protective films. Silicone release films have poor release force and are mainly used for some medium-viscosity silicone protective films.

Application

It is widely used in the processing of various products, such as electronic power and IT display screens. Mobile phones, LCD and PDA, medical, home appliance manufacturing, anti-counterfeiting materials, semiconductors, automobiles, nameplates, ceramic sheet manufacturing, tape production and die-cutting industries.

Technical Data Sheet

| Typical physical properties | |||

| Properties | Value | Unit | Test Method |

| Physical properties | |||

| proportion | 1.4 | g/cm³ | ASTM D792 |

| Optical properties | |||

| Transmittance | 92 | % | |

| Haze | 2.5 | % | ASTM D1003 |

| Mechanical behavior | |||

| Tensile strength (TD) | 240 | Mpa | ASTM D882 |

| (MD) | 230 | Mpa | ASTM D882 |

| Elongation at break (TD) | 180 | % | ASTM D882 |

| (MD) | 180 | % | ASTM D882 |

| Thermal properties | |||

| Molding shrinkage(TD) | 1.5 | % | ASTM D1204 |

| (MD) | 0 | % | ASTM D1204 |

| Release force | 200-700 | g/inch | 30cm/min 180℃ |

| Note: This test is for reference only and is not an absolute application indicator. | |||