Flame Retardant Film

Polyester Hard-coating Film

Description

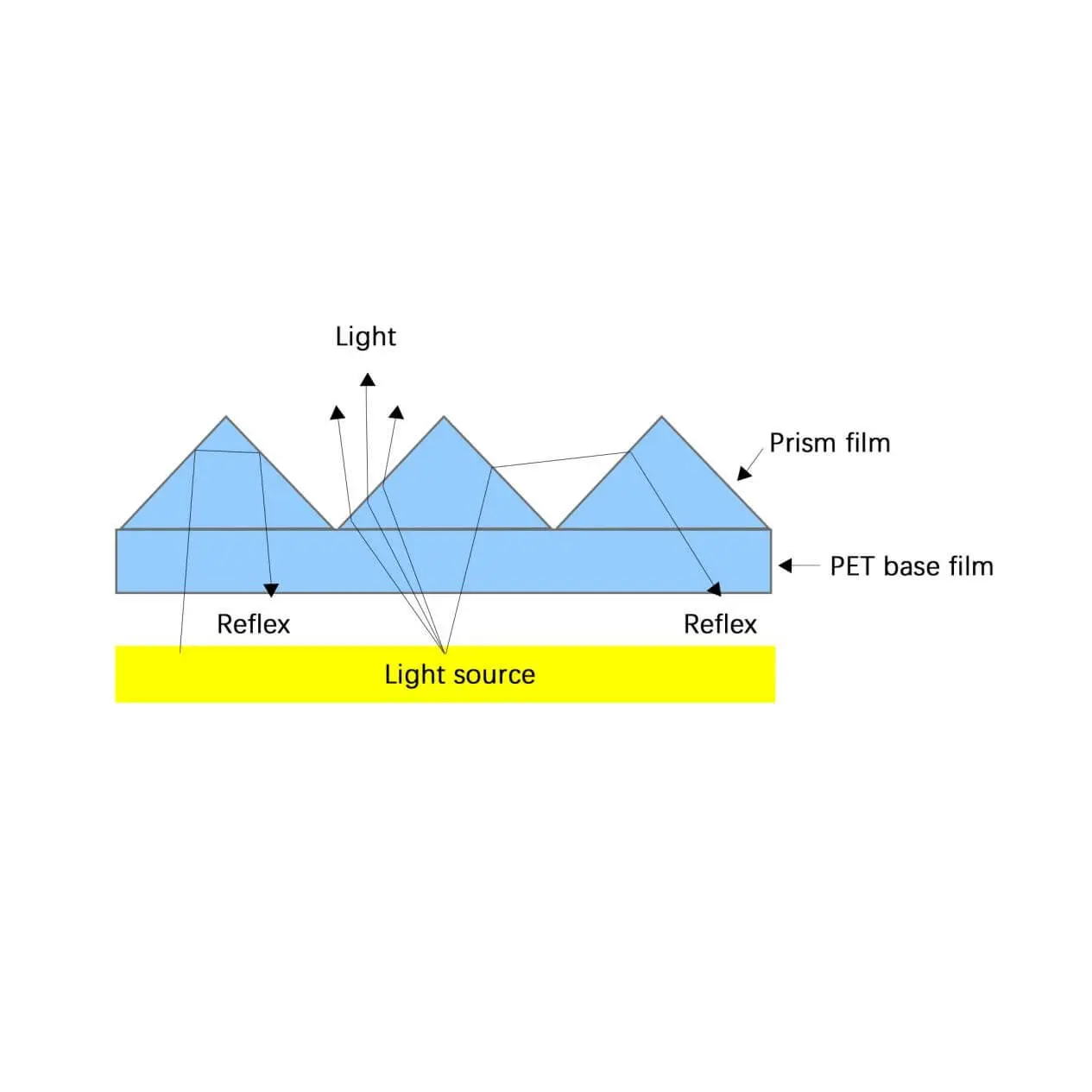

Brightness enhancing film (BEF, also known as prism sheet PCF) provides high gain brightness for LCD backlight modules and is one of the most important optical components of the backlight module; PCF produced using the principles of light recycling refraction and overall internal reflection is the same as the one on the market. Compared with existing brightness enhancement films, PCF has higher brightness gain. A single layer of optical film provides light concentration in the vertical and horizontal planes, while two layers of overlapping optical films can produce higher brightness gain in the vertical and horizontal planes.

LCD Backlight Modules Are Divided Into Two Structures According To The Position Of The Light Source:

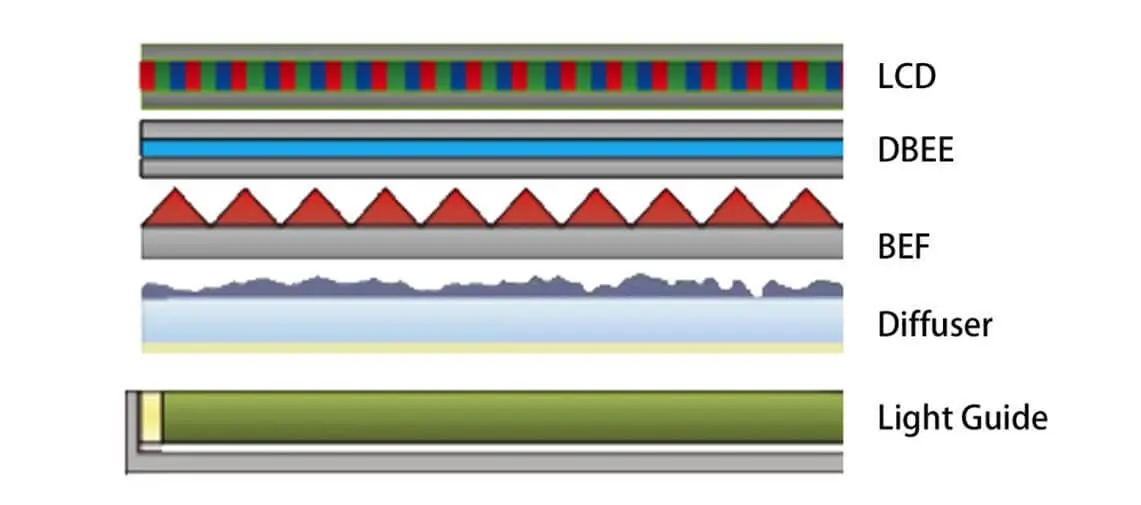

Edge Type: The light source is around the panel, and the light emitted from the edge of the screen is transmitted through the light guide plate to the center of the screen.

Direct Type: The light source is behind the panel, using a diffusion plate to evenly disperse the light and then using a brightness enhancement film to gather the light.

The brightness enhancement film is located on the lower diffusion film and is used to brighten the LCD panel. It has a special structure and the core of its manufacturing lies in the precision coating process. Brightness enhancement film (BEF) has a prismatic micro-structure, also known as prism film. It is composed of a three-layer structure of a light entrance surface, a transparent PET substrate, and a micro-prism structure light exit surface. By correcting the direction of the light and controlling the light intensity distribution, the light source is The scattered light is concentrated towards the front, and the unused light outside the viewing angle is recycled through light reflection, reducing the loss of light and at the same time improving the overall brightness and uniformity ultimately achieve the effect of increasing the brightness of the LCD panel and controlling the viewing angle.

LCD displays can be used in various specifications of televisions, computer monitors, mobile phones, digital cameras and other products, and have a wide range of downstream uses. The backlight module is a device that provides an external light source for TFT-LCD liquid crystal displays. The brightness enhancement film can be used as the core component of the display screen .

Classification:

- Normal Prism Sheet

The main function of the prism sheet is to guide the light emitted by the light source (including CCFL and LED) to increase the luminous efficiency.

- Multi-Functional Prism Sheet

Multifunctional prism sheet is a higher-end product that integrates the functions of prism sheet and diffuser sheet, and has better luminous efficiency than ordinary prism sheet.

- Micro-Lens Film

The micro-lens film also integrates the functions of the prism sheet and the diffuser sheet into one film through the mico-lens array structure. There are many panels that use two mico-lens films to replace the structure of one prism sheet plus two upper and lower expansion sheets. , the current main application products are 32″, 37″ and 40″ LCD TV panels.

- Reflective Polarizer

Or called DBEF (dual brightness enhancement film). According to experimental results, DBEF is currently the best product for improving luminous efficiency among all types of optical films. The luminous efficiency can be at least 30% higher than other products.

Production Process:

- Base material: The optical film produced by the company uses PET base film as the base material.

- Surface treatment: Perform surface cleaning and other treatments on the PET base film before coating to improve the adhesion of the base material surface and facilitate subsequent surface coating.

- Coating and curing: The rotating patterned die roller will evenly apply the prepared formula solution on the surface-treated PET base film in the form of prismatic lines on the patterned die roller, and at the same time, it will be coated with UV irradiation. Layer solidification.

- Online detection: Through the observation room at the other end of the production line, the quality of the finished product during the circulation process is detected in real time.

- Rewinding: Gather the finished product into a roll. The roll needs to be rolled with polished paper and fixed at both ends with plates.

- Sample preparation: take samples of finished coils.

- Testing: Test the sampled finished coils.

- The finished coils are put into storage.

Technical Data Sheet

| Typical physical properties | |||

| Properties | Value | Unit | Test method |

| Physical properties | |||

| proportion | 1.4 | g/cm³ | ASTM D792 |

| Optical properties | |||

| Transmittance | 7 | % | |

| Haze | 91 | % | ASTM D1003 |

| Mechanical behavior | |||

| Tensile strength (TD) | 210 | Mpa | ASTM D882 |

| (MD) | 140 | Mpa | ASTM D882 |

| Elongation at break (TD) | 105 | % | ASTM D882 |

| (MD) | 180 | % | ASTM D882 |

| Thermal properties | |||

| Molding Shrinkage (TD) | -0.56 | % | ASTM D1204 |

| (MD) | -0.85 | % | ASTM D1204 |

| Environmental testing | Test Methods | Aging degree(△ YI) | luminance attenuation(%) |

| High temperature/high humidity 500 hours | 65℃/95%RH | <0.1 | 4.0~5.0 |

| High temperature 500 hours | 85℃ | <0.1 | 4.0~5.0 |

| Low temperature 500 hours | -30℃ | <0.1 | 4.0~5.0 |

| Thermal shock | (-30℃×1Hr-65℃×1Hr) ×250cycles |

<0.1 | 4.0~5.0 |

| Note: This test is for reference only and is not an absolute application indicator. | |||