ID Card Film

Flame Retardant Film

Description

Polycarbonate (PC) films play a key role in touch screen technology. Due to its high transparency and durability, polycarbonate (PC) films are widely used in various touch screen devices such as smartphones, tablets, and electronic signature pads. It provides good touch sensing and accurate response, allowing users to perform touch operations with ease.

In addition, polycarbonate (PC) films are widely used in various display technologies. It acts as a protective layer for your display, protecting it from scratches and damage. In addition, polycarbonate (PC) film also has excellent optical properties and can provide clear and bright image display effects.

In addition, polycarbonate (PC) films are often used as protective films for electronic products. It covers the surface of your device, protecting your screen from scratches, fingerprints, and other contaminants. Not only does this protector keep your screen clean and smooth, it also extends the life of your device.

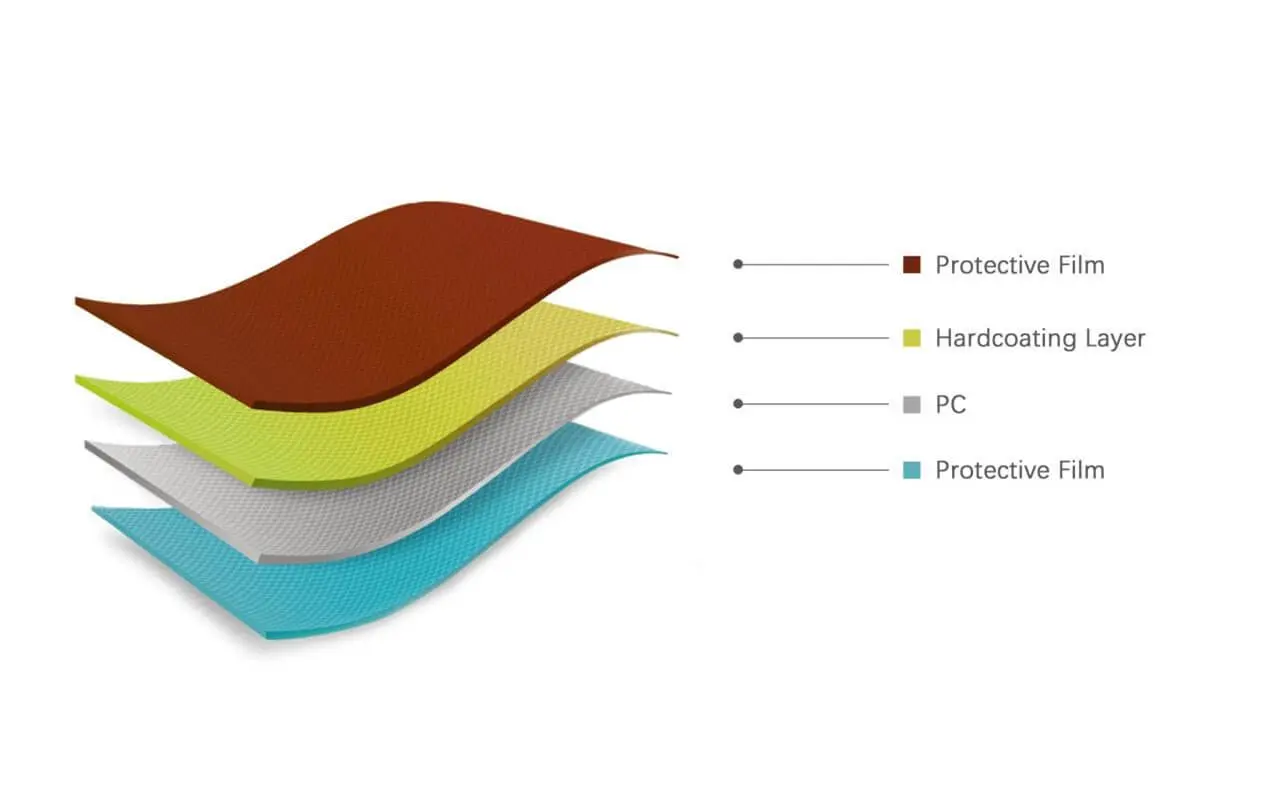

Kaixin’s polycarbonate (PC) is a polycarbonate sheet film with a double-sided or single-sided hard coating. It has the characteristics of small size, light weight and good sealing performance, and meets the needs of multi-function and intelligence in the electronic era. As well as the excellent abrasion resistance, optical clarity and excellent impact resistance of polycarbonate touch screen films, they are excellent candidates for smartphone and tablet touch screens, electronic product lenses, windows and keyboards.

Features and Applications

| Features | Application |

| Single/double layer hard coating, 4H pencil hardness | Touchscreens for handheld devices such as smartphones and tablets |

| Excellent impact and abrasion resistance, chemical resistance | Car navigation display, car audio buttons |

| Excellent optical performance | Electronic product lenses and windows |

| Excellent ink adhesion | Various types of printed electronic panels |

| etc. | etc. |

Technical Data Sheet

| Typical physical properties | |||

| Properties | Value | Unit | Test Method |

| Physical properties | |||

| water absorption | 0.2 | % | ASTM D570 |

| proportion | 1.2 | g/cm³ | ASTM D792 |

| pencil hardness | HB | 500g weights | 三菱铅笔ASTM D3363 |

| Mechanical behavior | |||

| Tensile Strength | 61 | Mpa | ISO 527-1 |

| Elongation at break | 6 | % | ASTM D638 |

| Bending strength | 92 | Mpa | ASTM D790 |

| Electrical properties | |||

| Arc resistance | 100 SEC | / | ASTM D495 |

| Thermal properties | |||

| Molding shrinkage | 0.5~0.7 | % | ASTM D955 |

| Vicat softening point | 148 | ℃ | ISO 306 |

| Note: This test is for reference only and is not an absolute application indicator. | |||