Hard-Coating Film

Touch Screen Film

Description

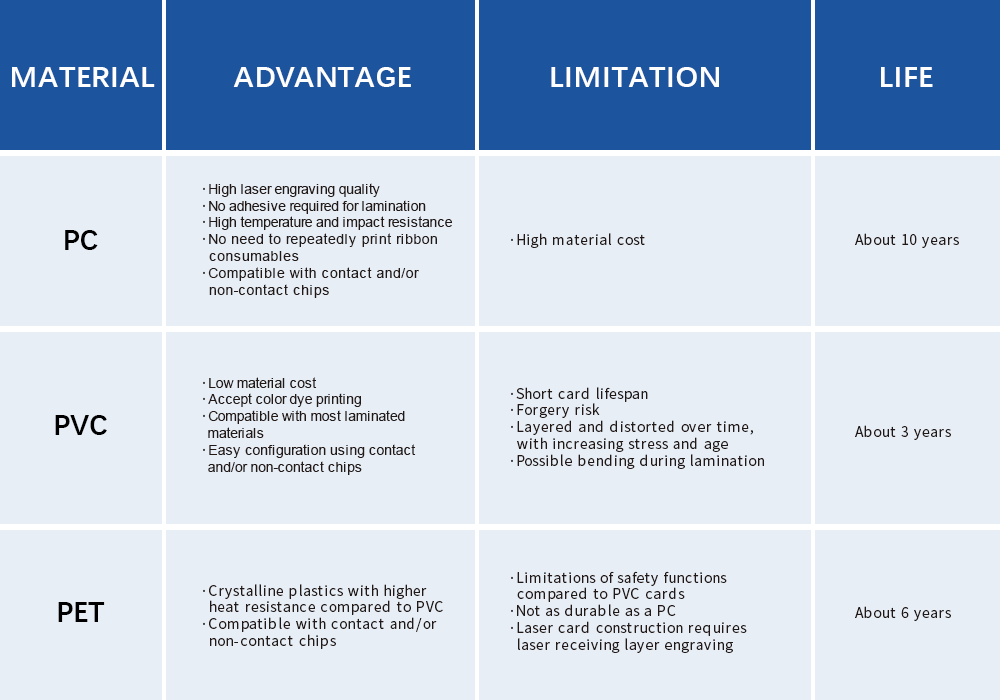

With the increasing degree of social informatization, ID cards, bank cards and other cards are used more and more widely. Due to the polyvinyl chloride (PVC) and polyethylene terephthalate-1,4-cyclic Hexane dimethanol ester (pet, poly (ethylene terephthalateco-1,4-cylclohexylenedimethylene terephthalate)) is cheap, so PVC or PETG is commonly used to prepare cards. With the improvement of people’s awareness of environmental protection and safety, cards made of PVC and PETG can no longer meet people’s needs. Polycarbonate (PC, polycarbonate) that can be recycled and reused gradually replaces PVC and PETG and gradually becomes the main material for making cards.

Safety is first based on good product quality. The ID card market requires the excellent performance of polycarbonate to provide the public with personal information that is secure and difficult to copy. Moreover, the PC material has good temperature resistance and hard material. It is no longer suitable to increase the holographic anti-counterfeiting effect by hot-printing a holographic anti-counterfeiting layer on the surface of the PC card. Currently, the holographic anti-counterfeiting layer is usually laminated inside the PC card to ensure that the PC The anti-counterfeiting strength and beauty of the card. However, the current common way to set up a holographic anti-counterfeiting layer is to hot-print the holographic anti-counterfeiting layer on the PC card film. However, this method can only hot-print holographic anti-counterfeiting layers with large areas, and cannot hot-print thin lines and other small-area holographic anti-counterfeiting layers. layer, which limits the application of the holographic anti-counterfeiting layer on PC cards. At the same time, the PC card adhesive film surface is relatively rough, and only hot stamping can be used, which requires high temperature resistance of the material. However, the holographic anti-counterfeiting layer prepared by cold stamping has a poor appearance, and will cause leakage and pasting.

Kaixin offers manufacturing and lamination processes specifically designed for high security level security ID cards. The secure ID film portfolio includes laser-printable clear films, opaque white films, clear films used as top or mid-layers, as well as co-extruded films and tough rigid films that enhance the security and durability of ID cards and other security documents. coating film. Excellent durability and security are the main reasons for using polycarbonate (PC) materials to make ID cards, passports and other materials.

Kaixin’s security PC film follows the accelerating industry trend of using more (thinner) card layers to accommodate additional security features, simplify the production process of ID cards and other security documents, and increase their durability.

Features and Applications

| Features | Applications |

| High and low temperature resistance, excellent high optical properties | Tachometer card |

| Low shrinkage, high flatness | Smart card inlay |

| Optimize surface texture for printing, hot stamping and lamination | Drving license, |

| Tight thickness tolerances control finished product thickness | Id cards, e-passports, military and police id cards |

| Excellent performance, especially suitable for window applications that require high image contrast and resolution | Residence permit, government employee id card |

| Excellent laser marking performance, providing extremely high resolution for laser etching of personalized information | Medical cards, certificate cards requiring card body performance and defense technology |

| Durable and can be used for a long time | Traffic card |

| Etc. | Etc. |

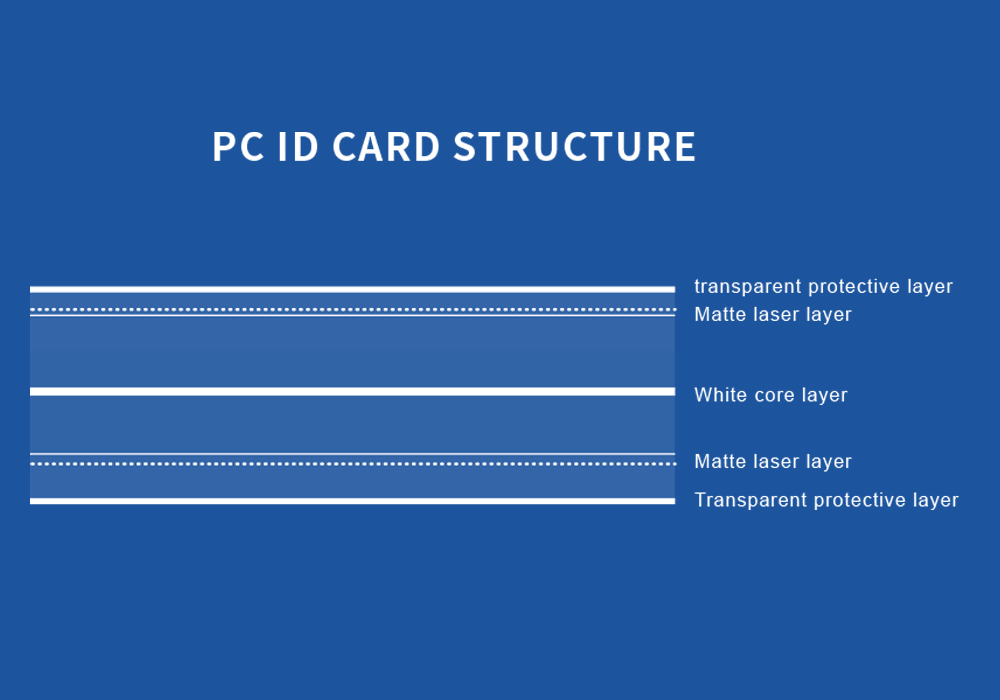

ID card laminated structure

Card laminated film is generally used for the pre-press preparation of personalized information on card-type documents. It is characterized by being see-through and embedded, anti-scratch and damage, strong and durable, and can be covered with heavy-color ink during personalized printing. It is often used for local positioning. Visual anti-counterfeiting is usually completed by multi-layout lamination after the card printing factory completes the bottom printing.

Printing material – anti-counterfeiting film – align the anti-counterfeiting film with the printing material and perform positioning welding – put it into the laminator as in the normal card production process – lamination – post-card production process – finished product. The finished film can be supplied in large sheets or rolls according to user requirements.

Technical Data Sheet

Laserable PC film

| Typical physical properties | |||

| Properties | Value | Unit | Test Methods |

| Physical properties | |||

| water absorption | 0.2 | % | ASTM D570 |

| proportion | 1.2 | g/cm³ | ASTM D792 |

| pencil hardness | HB | 500g砝码 | 三菱铅笔ASTM D3363 |

| Mechanical behavior | |||

| Tensile Strength | 61 | Mpa | ISO 527-1 |

| Elongation at break | 6 | % | ASTM D638 |

| Bending strength | 92 | Mpa | ASTM D790 |

| Electrical properties | |||

| Arc resistance | 100 SEC | / | ASTM D495 |

| Thermal properties | |||

| Molding shrinkage | 0.5~0.7 | % | ASTM D955 |

| VST | 148 | ℃ | ISO 306 |

| Note: This test is for reference only and is not an absolute application indicator. | |||

Non-laserable Overlay film

| Typical physical properties | ||

| Properties | Value | Unit |

| Physical properties | ||

| thickness | 75~800 | μm |

| Thickness tolerance | 75-175μm,±5%;200-800μm,±3% | / |

| color | White | / |

| density | 1.22 | g/cm³ |

| Squareness | ±0.5 | mm/m |

| Transmittance | 75-250μm,≤5%;251-800μm,≤3% | / |

| Mechanical behavior | ||

| Surface Tension | ≥38 | dyn/cm |

| Note: This test is for reference only and is not an absolute application indicator. | ||

Core layer film

| Typical physical properties | ||

| Properties | Value | Unit |

| Physical properties | ||

| thickness | 50~250 | μm |

| Thickness tolerance | 50-250μm,±8%;100-250μm,±5% | / |

| color | Clear | / |

| density | 1.2 | g/cm³ |

| Roughness | 5~12 | μm |

| Transmittance | ≥85 | % |

| Mechanical behavior | ||

| Surface Tension | ≥38 | dyn/cm |

| Note: This test is for reference only and is not an absolute application indicator. | ||

Transparent PC film

| Typical physical properties | ||

| Properties | Value | Unit |

| Physical properties | ||

| thickness | 50~250 | μm |

| Thickness tolerance | 50-250μm,±8%;100-250μm,±5% | / |

| color | Clear | / |

| density | 1.2 | g/cm³ |

| Roughness | 5~12 | μm |

| Transmittance | ≥85 | % |

| Mechanical behavior | ||

| Surface Tension | ≥38 | dyn/cm |

| Note: This test is for reference only and is not an absolute application indicator. | ||