Explosion-proof Film

ID Card Film

Description

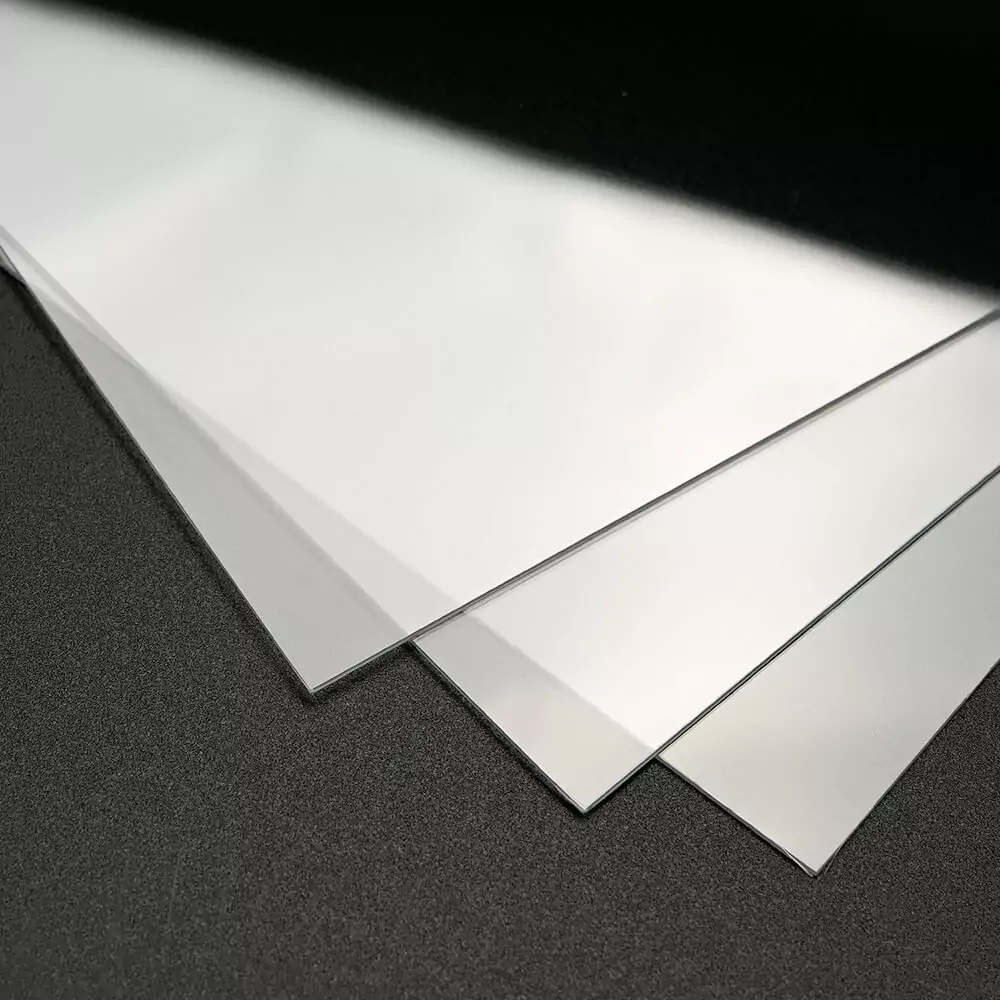

Kaixin offers a wide range of hard coated polycarbonate (PC) products with enhanced properties to meet the broad needs of the market.

Polycarbonate hardened film offers excellent abrasion, scratch and chemical resistance, higher hardness and impact resistance.

Kaixin offers single or double sided hardened coatings to meet the stringent requirements of the appliance, nameplate, membrane touch switch and lens markets.

Hard coating on polycarbonate (PC) is optically clear, highly scratch-resistant, and provides excellent protection from chemical solvents and cleaning agents. These hardened PC films are primarily used for optoelectronic purposes and are ideally suited for use as the top layer of flat panel or LCD displays since scratch and chemical resistance are highly valued during the product design process.

Features

- Excellent hardness and impact resistance.

- Suitable viscosity: easy to stick and easy to tear.

- Stable peeling force: The cured film changes very little over time, that is, the smaller the increase in peeling force, the better.

- Good weather resistance: under sunlight conditions, the service life is as long as half a year to one year.

- Long storage period: the quality will not change after being stored in the warehouse for more than one year.

- No pollution and no corrosion: The adhesive is inert and the hardened film will not react chemically with the surface of the adhered material.

- Excellent mechanical properties: PC hardened film meets the tensile strength, elastic modulus, elongation, etc. required by customers in various industries.

Applications

- Electronic and electrical window panels, air conditioning panels, membrane switches, buttons, etc.

- Automotive in-mold injection molding, in-mold labeling, interior parts, etc.

- Communication products, digital product covers, lenses, etc.

- Products that require high hardness and impact resistance, such as anti-fog goggles, LCD screens, etc.

Technical Data Sheet

| Typical physical properties | |||

| Properties | Value | Unit | Test Methods |

| Physical properties | |||

| water absorption | 0.2 | % | ASTM D570 |

| proportion | 1.2 | g/cm³ | ASTM D792 |

| pencil hardness | HB | 500g砝码 | 三菱铅笔ASTM D3363 |

| Mechanical behavior | |||

| Tensile Strength | 61 | Mpa | ISO 527-1 |

| Elongation at break | 6 | % | ASTM D638 |

| Bending strength | 92 | Mpa | ASTM D790 |

| Electrical properties | |||

| Arc resistance | 100 SEC | / | ASTM D495 |

| Thermal properties | |||

| Molding shrinkage | 0.5~0.7 | % | ASTM D955 |

| VST | 148 | ℃ | ISO 306 |

| Note: This test is for reference only and is not an absolute application indicator. | |||