Textured Polycarbonate Film

Digital Printing Film

Description

Kaixin’s anti-fog film is a high-quality engineering thermoplastic film widely used in a variety of industries.

In the fields of advanced driver assistance systems (ADAS) and monitoring systems/identity authentication systems, camera modules (CCM) and imaging elements (CCD, CMOS) are required to be immune to changes in the surrounding environment (humidity, temperature, rainfall, backlight). to obtain accurate image information. If there is a temperature difference or a drastic change in air pressure between the inside and outside of the CCM cover glass/lens, water droplets will be generated on the surface (inner surface) of the cover glass/lens, causing fogging.

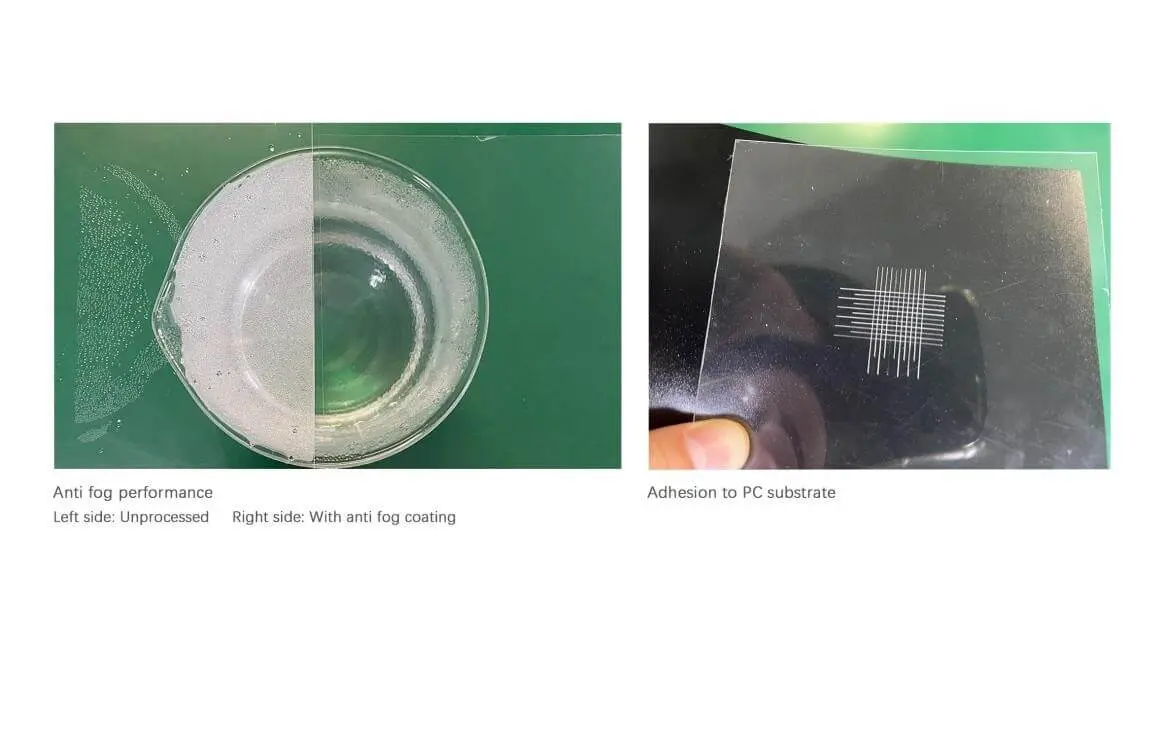

After fogging, light will be scattered, affecting visibility and the collection of image information. Using the anti-fog coating developed by Kaixin to coat the inner surface of the cover glass/lens can solve the problems caused by fogging. Because the anti-fog film has good transmittance/durability/water resistance, it can improve the reliability of vehicle cameras, surveillance cameras, various high-performance cameras, etc., so that image sensors and imaging components can obtain accurate image information.

Kaixin anti-fog film is a polycarbonate film coated on one or both sides. The anti-fog effect will not fail even in very humid environments. It is highly durable when wet and retains its anti-fog properties after repeated cleaning with commercial glass and lens cleaners. The main principle is to prevent surface condensation and at the same time distribute moisture evenly on the surface, thus preventing water molecules from gathering in local areas to form water droplets.

Features

Kaixin’s anti-fog films offer abrasion resistance, impact resistance and excellent optical clarity. In high temperature and high humidity environments, it still has high light transmittance, which can effectively improve visual effects and safety performance. It is widely used in automobiles, ships, glasses, safety masks, medical equipment and other fields to reduce accidents caused by blurred vision.

Because this product has high light transmittance, UV protection, high surface hardness, high smoothness, no crystal points, and good printing and electroplating properties.

It is also the best choice for anti-fog packaging, protective masks, anti-fog lenses, anti-fog windows, windows and other products.

Applications

- Swimming goggles, ski goggles, racing helmet safety, etc. in the sports safety industry.

- Rearview mirrors, front windshields, etc. in the automotive industry.

- Supermarket glass freezers, cold storage instrument glass and other refrigeration equipment.

- Building exterior wall decoration (excellent light transmittance, no visual obstruction).

- Bathroom and shower mirrors (the mirror surface is completely undisturbed by fog during bathing and is still clearly visible).

- Commercial freezers and deli cabinet doors (no electricity required, no power consumption, no radiation, energy saving and emission reduction).

- Industrial safety and sports hats, glasses and face masks (enhanced safety and security).

Performance Evaluation

– Please see the attachment for the evaluation results table

| Test | Hydrophilic, water-absorbent type | |

| Anti-fog coating performance

evaluation |

Adhesion | No peeling |

| Anti-fog performance | No fogging, appearance change | |

| Durability | No fogging, appearance change | |

| Friction resistance | No fogging, appearance change | |

| Evaluation results (PC resin substrate) | ||

Technical Data Sheet

| Typical physical properties | |||

| Performance | Value | Unit | Test method |

| Physical properties | |||

| Water contact angle | 20±5 | ° | / |

| Proportion | 1.2 | g/cm³ | ASTM D792 |

| Coating adhesion | 5B | / | / |

| Mechanical behavior | |||

| Tensile Strength | 61 | Mpa | ISO 527-1 |

| Elongation at break | 6 | % | ASTM D638 |

| Bending strength | 92 | Mpa | ASTM D790 |

| Flexural modulus | 2230 | Mpa | ASTM D790 |

| Optical properties | |||

| Transmittance | >89 | % | ASTM D1003 |

| Haze | <1 | % | ASTM D1003 |

| UV light transmittance 350nm | <1 | % | ASTM D1003 |

| Thermal properties | |||

| Molding shrinkage | 0.5~0.7 | % | ASTM D955 |

| Microcard softening point | 148 | ℃ | ISO 306 |

| Note: This test is for reference only and is not an absolute application indicator. | |||