Full Fit Optical Clear Adhesive (OCA)

Glossy Polycarbonate Film

Description

As the development of automobile intelligence accelerates, vehicle-mounted displays are developing towards large size, multi-screen, high-definition, interactivity, and multi-formatization. There are also higher requirements for display performance, including high contrast, low reflectivity, wide viewing angles, high brightness, touch controls, fast response, and more. In addition, the novel design of the details and structure of the vehicle display screen can also play an unexpected role in improving product competitiveness. Therefore, the “all-in-one black” technology that can create novel, eye-catching, beautiful and technologically advanced vehicle display effects will become one of the trends.

Features

- Excellent anti-blue light performance (blue light band blocking 25~35%).

- High reliability (blue light resistance, UV resistance).

- High adhesion.

- Excellent optical properties / acid-free.

- Excellent UV resistance (more than 99% UV band blocking).

- High reliability (UV resistance).

- Uniform color and gloss, stable performance / acid-free.

Applications

- Suitable for mobile phones, tablets, laptops, and other small and medium-sized sizes.

- Suitable for charging stations, access control screens, outdoor face recognition screens and other outdoor screens.

- Suitable for smart wearables, smart home appliance display panels, smart switch panels, smart door locks, etc.

- Suitable for matching materials with high refractive index.

Integrated black technology for car display

The ink area and the window area of most current display screens are usually of different colors. When the display screen is in the rest state, there is an obvious color difference between the display area and the edge ink area, resulting in poor visual effects.

With the improvement of consumer aesthetics, everyone’s pursuit of beauty is getting higher and higher. Therefore, there is a device that can make the color difference between the display area and the edge ink area of the central control screen difficult to distinguish with the naked eye when the screen is idle, making the car display more visible. It is a technology that blends into the environment and enhances the high-end feel of the cockpit. This is “all-in-one black”.

How to achieve the “all black” effect

“All-in-one black” can create a seamless visual perception, making the product appearance more high-end, grand, beautiful and technological, while creating product differentiation, thereby increasing consumers’ desire to purchase. In addition to in-vehicle displays, it is also widely used in smart terminals such as smartphones, smart wearables, and mid- to high-end touch laptops. So what if the “all black” effect is achieved?

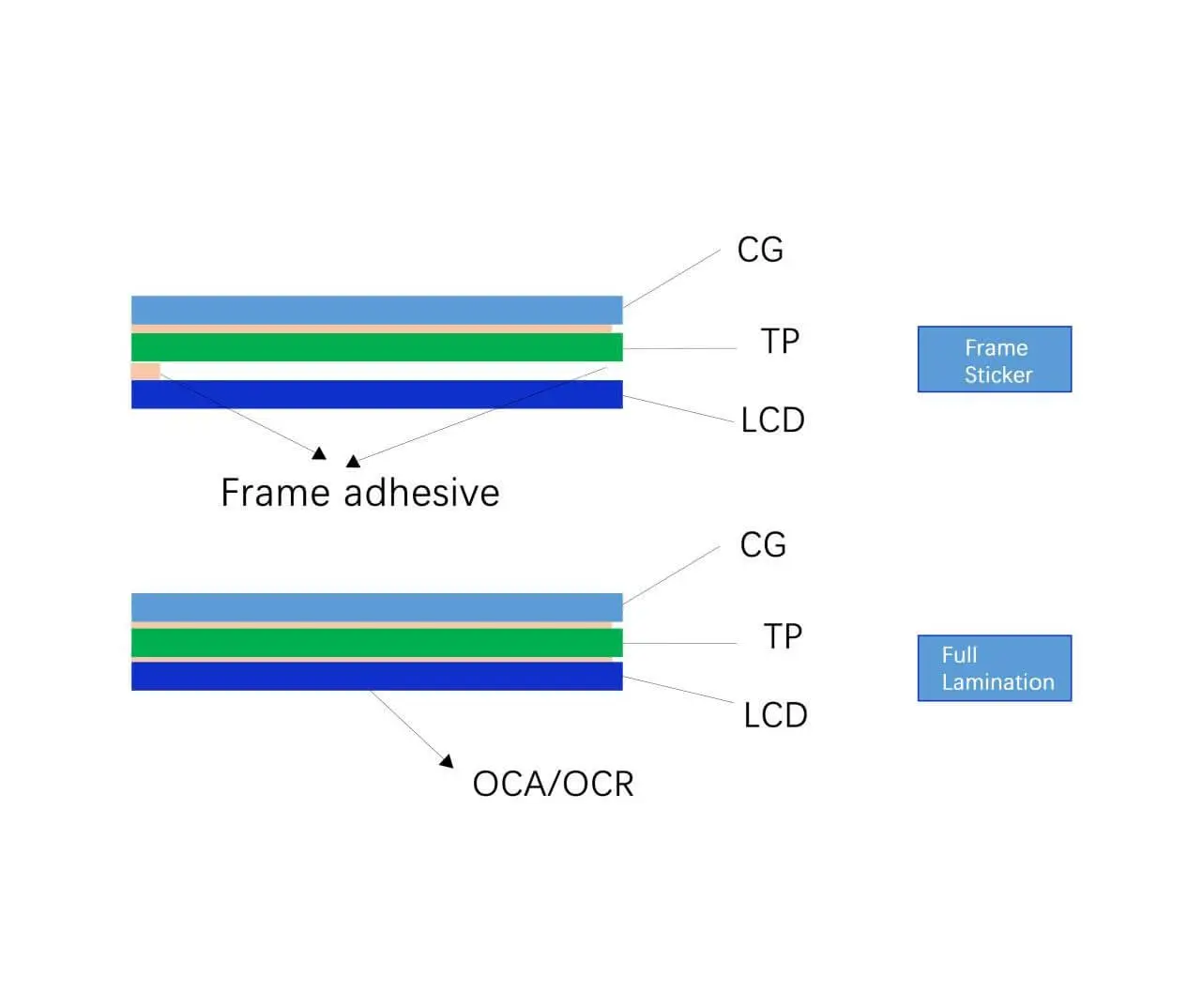

The realization of one-piece black has a great relationship with the components of the display screen and the process methods such as TFT display screen, polarizer, lamination method, lamination glue, frame ink, coating, etc. It requires the perfect matching of various factors. The full fit of the screen contributes to the black effect.

In the case that the TFT glass screen is no longer changeable, there are three ways to implement the “one-piece black” panel.

Silk screen printing method

After the cover is CNC-strengthened, screen-printed/vapor-deposited with a black frame, a layer of IR ink is semi-transparently printed on the window area or button area of the glass cover. By adjusting the ink color and transmittance, the integrated black color is achieved. Effect.

Things to note when using semi-transparent printing:

The choice of semi-transparent black ink should be in the same color system as the border color, and the color should be close. Too dark and too light will cause color differences.

Transmittance control: Depending on the brightness of the LED light and the use environment, the transmittance ranges from 1% to 50%. Currently, the two most commonly used ones are 15±5% and 20±5%.

Coating

Through magnetron sputtering and optical principles, an inorganic film is directly coated on the glass cover, and the reflection, transmission, and color difference of the film window area are adjusted, so that the color of the touch display window and the silk screen frame are consistent. The transmittance can reach 80% and the reflectivity is less than 2%.

The cover is made of semi-permeable material

In addition to the two post-processing processes of silk screen printing and coating, you can also directly use semi-transparent materials to achieve the “all-in-one black” effect. The material can be plastic or glass.

In the one-piece black processing of plastic materials, toner is usually added to the resin material, and the “one-piece black” effect is achieved by adjusting the amount of toner added in the material; for glass, color can be added during production, or it can be dyed. . As for glass materials, you need to rely on the original glass factory for preparation or use a semi-permeable film.

Directly using semi-permeable material processing methods can achieve a good “all-in-one black” visual effect, and the cover surface has consistent permeability.

Using smoked OCA/OCR

Judging from the structure of the display screen, the effect of integrated black is the color consistency displayed by the light passing through the cover plate, TP layer, LCM layer, and fully bonded optical glue. Therefore, in addition to the cover plate, TP, and LCM liquid crystal layer, the color of the optical glue part can also be adjusted to reduce the color difference between the display part and the edge part.