Acrylic Film

Regular Optical Clear Adhesive ( OCA )

Description

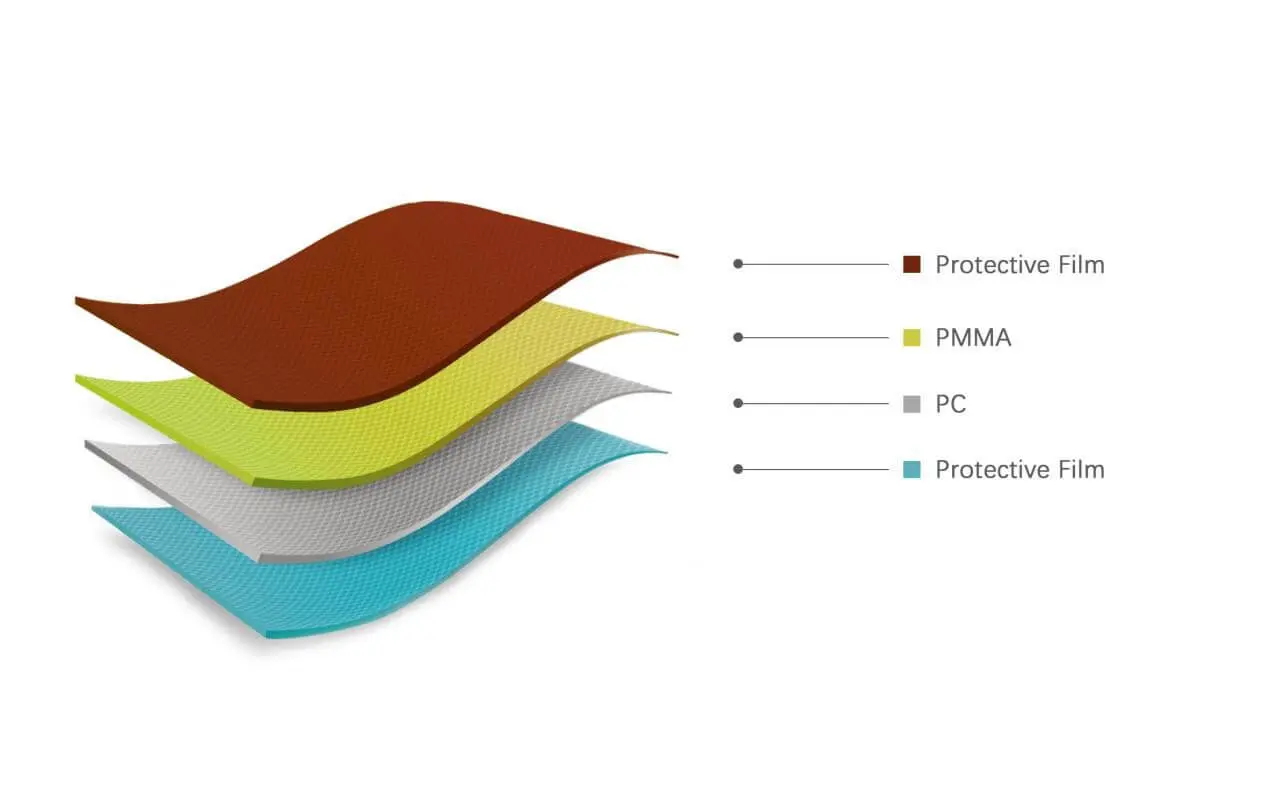

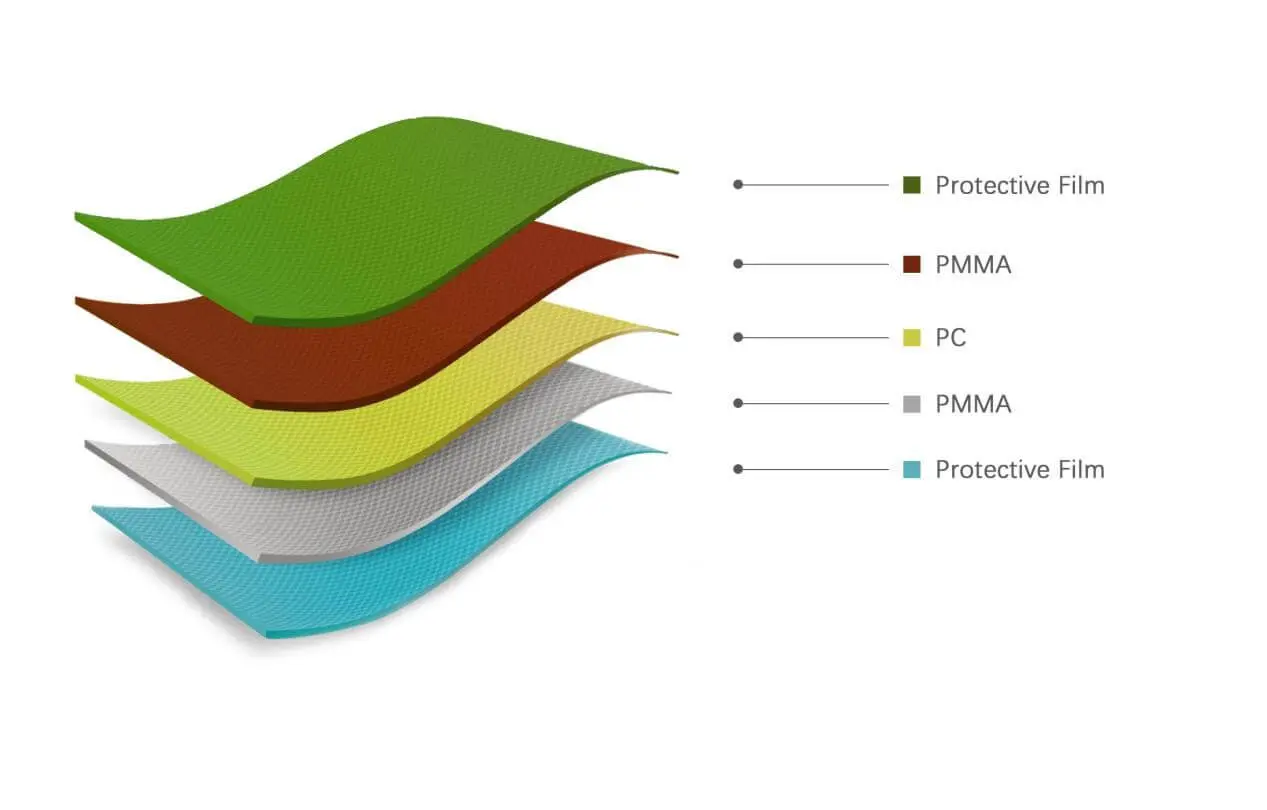

PC and PMMA composite sheet is an optical grade sheet with a transparent imitation glass effect. It is made by co-extrusion of PMMA and PC (different from plastic alloys), including PMMA layer and PC layer. Its surface hardness can reach that of hardened acrylic, and it also has the toughness of PC sheets and can withstand greater impact, making it very suitable as a material for mobile phone casings. After texture production, you can get a good flowing and colorful glass effect. But it must be distinguished from plastic alloy and high-pressure composite panels. The structure of the panels is similar to composite co extruded sheets.

In the actual product application process, because PMMA has good hardness and wear resistance, it is generally used on the outside, while PC has good toughness, so it is used as the inner layer.

Currently, PC and PMMA composite sheets are available in two specifications: two-layer sheets and three-layer sheets.

Two-layer sheet: thickness 0.2 mm to 2mm, such as mobile phone covers, car interiors, mobile phone protective cases, etc.

Three-layer sheet: thickness 0.5mmto2.0mm, such as car panels, MP3, MP4, mobile phone lenses, buttons, camera lenses, decorative parts, backlights, touch screen wall patching and other electronic product window panel lenses.

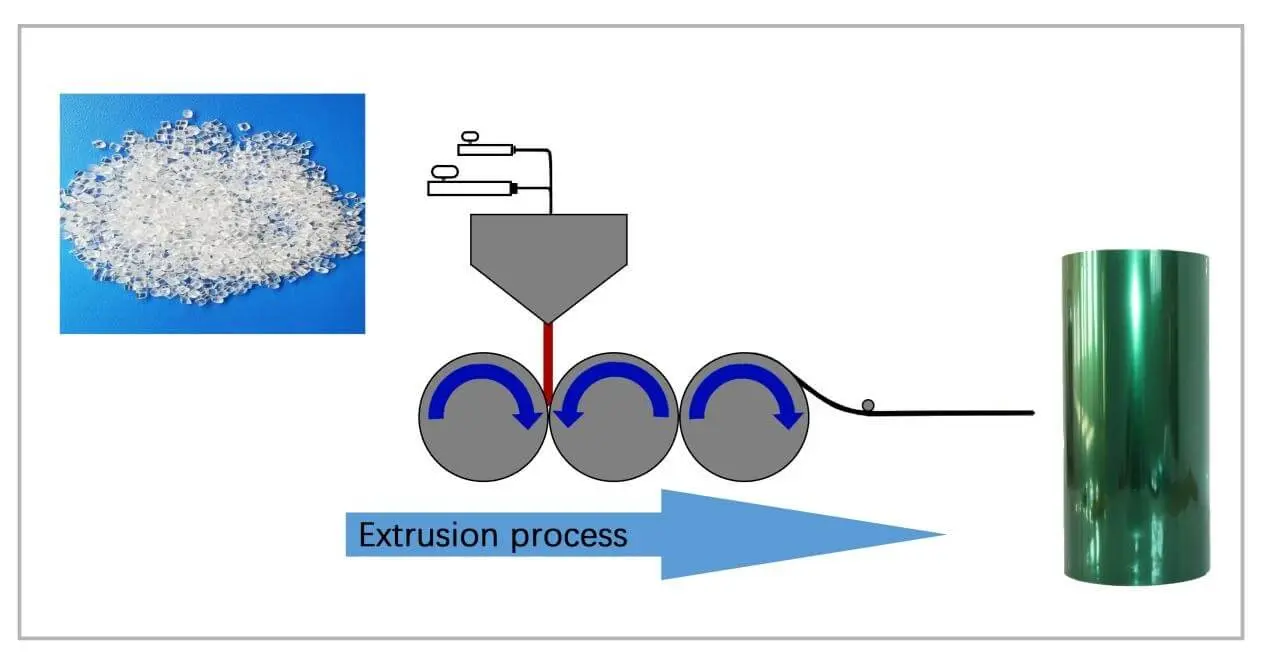

How Are PC and PMMA Composite Sheet Formed?

The concept of PC and PMMA composite sheet is similar to composite film, rather than the current hotter plastic alloy. There are three main methods for forming composite films:

Sequential extrusion composite: refers to a composite material produced by extruding one raw material onto another formed film during the film processing process.

Adhesive type: refers to a composite material made by combining two different types of films through an adhesive.

Co-extrusion composite film: Co-extrusion composite uses several extruders to squeeze different types of resins into a composite die at the same time. Each layer of resin is combined inside or outside the die to form a whole. After extrusion and compounding, After cooling and shaping, it becomes a composite film.

Features

- Excellent transparency: The high transparency of PC and PMMA gives the composite sheet a clear and bright appearance, which can provide good visual effects.

- Good impact resistance: The excellent impact resistance of PC makes the composite sheet have excellent impact resistance, which can reduce the risk of cracking and damage when stressed.

- Strong weather resistance: PC and PMMA composite sheet has good weather resistance, can resist ultraviolet radiation, oxidation and color change, and is suitable for indoor and outdoor environments.

- High temperature stability: PC and PMMA composite sheets maintain stability at high temperatures and can maintain stable physical properties and appearance within a certain temperature range.

- Good processability: PC and PMMA composite sheets can be processed by injection molding, extrusion and calendering, and are suitable for various complex shapes and size requirements.

Applications

- Mobile phone screen cover: Because PC and PMMA composite material has excellent transparency and impact resistance, it is widely used in the manufacture of mobile phone screen covers. In the manufacturing process of mobile phone covers, PC and PMMA composite materials can be made into screens of different shapes and sizes, making the mobile phone screen stronger, more durable, transparent and beautiful.

- Mobile phone back cover: PC and PMMA composite sheet is easy to process, resistant to falls and wear. It can achieve 3D glass effect through texture design and 3D high pressure molding. Different texture designs and color effects can be satisfied, and it can be made lighter and thinner than glass. , is currently the most powerful competitor for 3D glass back covers.

- Touch screen, lens sheet: PC and PMMA composite sheet has undergone AR ,AG and AF coating application process to achieve anti reflection, anti glare, anti fingerprint, anti fouling and other effects. It is widely used in Touch panels, Lens and other window lenses, mobile phones, Tablet computers, monitor lenses, vehicle displays, equipment panels, membrane switches, etc.

- Smart leather case thick plate: PC and PMMA composite plate can also be used as a protective cover substrate for smartphone designs. Through excellent machining performance and thermal bonding performance, it can achieve various visual effects desired by customers.

- Automotive interior parts : Automotive interior parts require high strength, beautiful appearance and durability. The PC and PMMA composite sheet has high transparency, good flexibility and stable color, and can create exquisite black technology interior decoration effects.

Technical Data Sheet

| Typical physical properties | |||

| Properties | Value | Unit | Test method |

| PC PMMA composite sheet physical properties | |||

| Physical properties | |||

| Physical properties | 0.2 | % | ASTM D570 |

| Density | 1.2 | G/cm³ | ASTM D792 |

| Hardness | HB | 500g | Mitsubishi pencil ASTM D3363 |

| Optical properties | |||

| Transmittance | >90 | % | ASTM D1003 |

| Haze | <1 | % | ASTM D1003 |

| Transmittance | |||

| Tensile strength | 50 | Mpa | ISO 527to1 |

| Elongation at break | 15 | % | ASTM D638 |

| Bending strength | 150 | ° | ASTM D790 |

| Electrical properties | |||

| Arc resistance | and | and | JISKto6911 |

| Thermal properties | |||

| Molding shrinkage | 0.2~0.6 | % | ASTM D955 |

| VST | 96 | ℃ | ASTMDto1525 |

| PMMA PC PMMA composite sheet physical Properties | |||

| Physical properties | |||

| Water absorption | 0.2 | % | ASTM D570 |

| Density | 1.2 | gandcm³ | ASTM D792 |

| Hardness | HB | 500g砝码 | 三菱铅笔ASTM D3363 |

| Optical properties | |||

| Transmittance | >90 | % | ASTM D1003 |

| Haze | <1 | % | ASTM D1003 |

| Mechanical properties | |||

| Tensile Strength | 61 | Mpa | ISO 527to1 |

| Elongation at break | |||

| Bending strength | >150 | ° | ASTM D790 |

| Electrical properties | |||

| Arc resistance | NO Trace | and | JISKto6911 |

| Thermal properties | |||

| Molding shrinkage | 0.2~0.6 | % | ASTM D955 |

| VST | 96 | ℃ | ASTMDto1525 |

| Note: This test is for reference only and is not an absolute application indicator. | |||