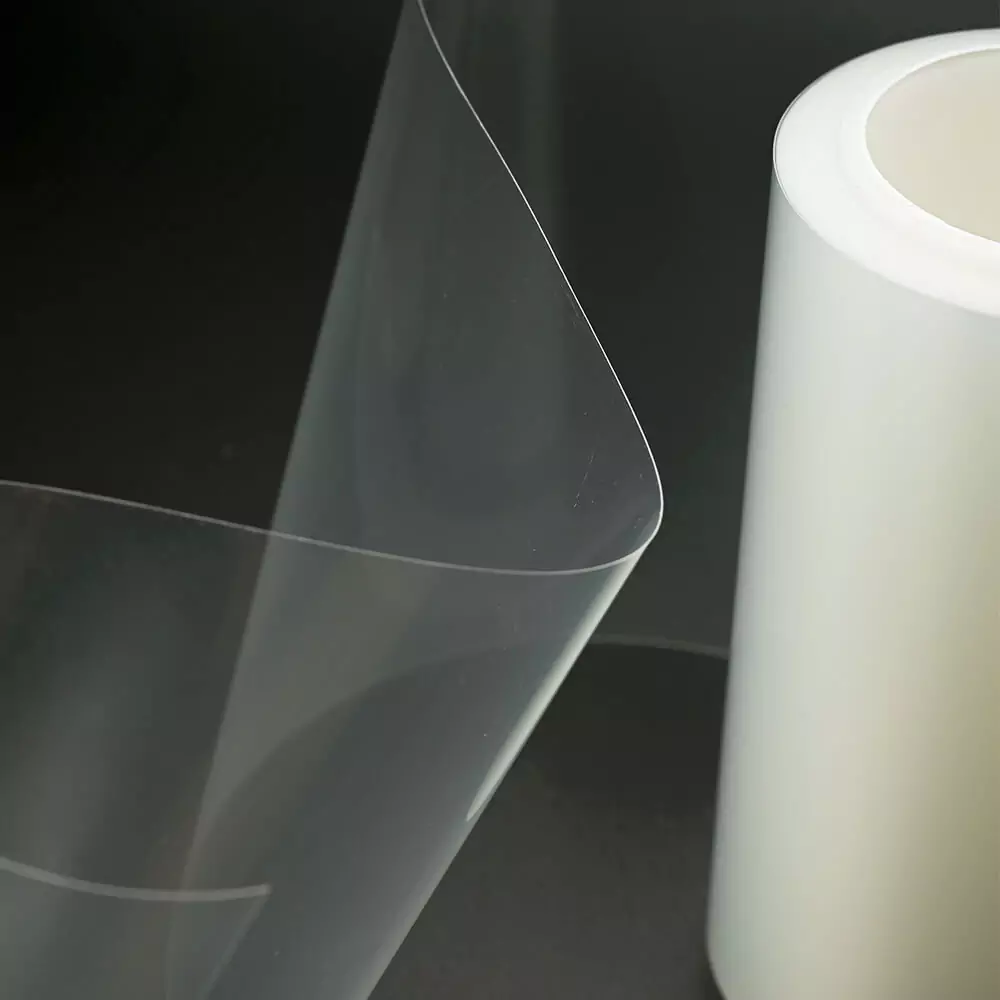

Silicone-free Release Film

Polyester Film For Home Appliances

1. Characteristics of Optical PET film

PET type optical film coating is a new material with excellent properties such as high light transmittance, high reflectivity, and high conductivity. It mainly consists of PET substrate and coating, of which the coating is the key part. Through precise manufacturing processes, nanoscale materials are coated on the PET substrate to form a thin and uniform film. This film has many unique properties, such as high transmittance, high reflectivity, high conductivity, etc.

2. Advantages of Optical PET film:

– High transparency

PET optical base film has excellent optical transparency, ensuring clarity and transparency under various light conditions, and is suitable for various optical applications.

– Low light loss

The material has low light loss characteristics, which can minimize light scattering and absorption and improve light transmission efficiency.

– Excellent optical performance

PET optical base film can maintain excellent optical stability under a wide temperature range and different humidity conditions, ensuring long-term stable performance.

– High tensile strength

PET optical base film has high tensile strength and can withstand a certain tensile force, maintaining the integrity and stability of the material.

– Good wear resistance, able to resist friction and wear and extend service life.

– PET optical base film has excellent folding resistance and is not prone to creases and cracks, making it suitable for applications that require frequent folding.

– It has a high heat distortion temperature and can maintain stable shape and performance in high temperature environments.

– It has excellent heat aging resistance, can maintain stable performance under long-term high temperature exposure, and is not prone to yellowing, embrittlement and other phenomena.

– It can resist the erosion of strong corrosive media such as acids and alkalis, and maintain the stability and integrity of the material.

– This material has good tolerance to a variety of organic solvents, is not prone to swelling, deformation, etc., and is suitable for applications in various chemical environments.

3. Application of optical PET films in the electronic field

LCD control panel: Optical PET protective film has excellent optical properties such as high transmittance and high surface smoothness in LCD displays. It is used as key components such as external diffusion film, brightening film, reflective film, anti-static protective film and protective film for touch display screens. In LCD displays, optical films are in high demand, occupying 15-20 times the panel area, and costing approximately 15-20% of the total cost of LCD displays.

Tablet PC: Optical PET protective film accounts for more than 80% of the cost of tablet computer panel products. Optical films play an important role in the manufacturing process of tablet computers and are mainly used for film enhancement, backlight control module films, color filters, polarizers and other components.

Optical devices: Optical PET films can be used to manufacture various optical devices, such as lenses, filters, reflectors, etc. Its high light transmission and surface smoothness make it the material of choice for improving the performance and protection of optical components.

Lighting industry: Optical PET films can be used as key components such as anti-reflection films, reflective films and anti-glare films in lighting products to improve lighting effects and optical transmission efficiency.

Automotive field: Optical PET films are increasingly used in automotive dashboards, central control screens, navigation displays and vehicle display systems. It can be used as a protective film, reflective film or anti-reflection coating to provide high-quality display and durability.

Medical equipment: Since optical PET film has low haze, high transmittance and good chemical stability, its application in medical equipment is also important. For example, optical PET films are used in screen protectors for medical monitors, scanners, and surgical instruments to provide clear images and reliable protection.

Solar energy industry: Optical PET films can be used as protective films for solar panels and solar collectors. It is weather-resistant, high-temperature resistant and UV-resistant, which improves solar energy conversion efficiency while extending the life of the equipment.

Overall, optical PET films play an important role in many fields, and their excellent optical properties and plasticity make them an ideal material choice. With the continuous advancement of technology and the increase in demand, the application prospects of optical PET films in more fields will continue to expand.