Description

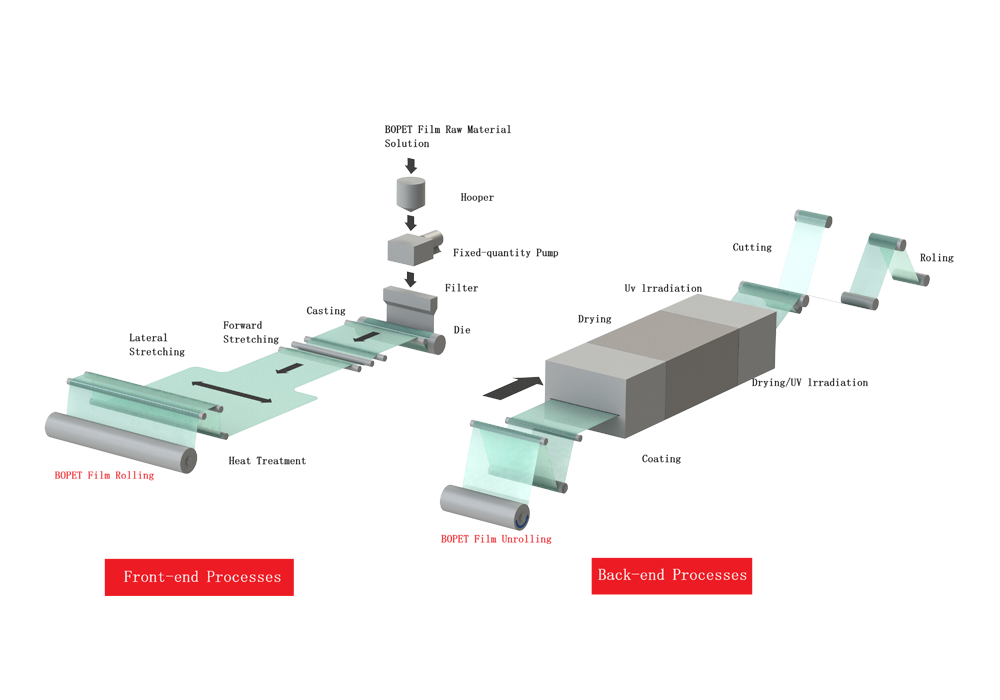

Polyester film (BOPET) is the abbreviation of biaxially oriented polyester film. It is made from polyethylene terephthalate slices and undergoes mixing, drying and water removal, extrusion and melting, filter filtration and die extrusion. The film is made into thick sheets through processes such as longitudinal stretching, transverse stretching, and traction and winding to form a biaxially stretched film. Polyester film has the characteristics of high tensile strength, good optical properties, high elastic modulus, good toughness and good thermal stability. It also has the advantages of acid resistance, alkali resistance and good air tightness.

Types

- Biaxially oriented polyester film (BOPET) is a high-grade film made of glossy materials that has been dried, melted, extruded, cast and stretched vertically and horizontally. It has a wide range of uses. BOPET film has the characteristics of high strength, good rigidity, transparency, and high gloss: odorless, tasteless, colorless, non-toxic, and outstanding strength and toughness: its tensile strength is 3 times that of PC film and nylon film, and its impact strength is BOPP 3-5 times that of the film. It has excellent wear resistance, folding resistance, pinhole resistance and tear resistance. It has extremely small heat shrinkage. It only shrinks 1.25% after 15 minutes at 120℃, it has good antistatic properties, easy to carry out vacuum aluminum plating, and can be coated with PVDC to improve its heat sealability, barrier properties and printing adhesion.BOPET also has good heat resistance, excellent cooking resistance, and low temperature freezing resistance properties, good oil resistance and chemical resistance, etc. BOPET films cannot be dissolved by most chemicals except nitrobenzene, chloroform, and benzyl alcohol. However, BOPET will be corroded by strong alkali, so care should be taken when using it. BOPET film has low water absorption and good water resistance, and is suitable for packaging foods with high water content.

- Uniaxially oriented polyester film (CPET ) is a film that uses semi-matte material (titanium dioxide is added to the raw material polyester slices), and is dried, melted, extruded, cast and stretched longitudinally. The film has the lowest grade and price and is mainly used for pharmaceutical tablet packaging. Due to less usage, manufacturers rarely produce it on a large scale, accounting for about 5% of the polyester film field.

Applications

● Packaging field : Functional polyester films are widely used in packaging of food, medicine, daily chemicals, electronics, etc. Because of its good low-temperature heat sealing performance, high strength, and high definition, it can be used to make various composite packaging materials, such as stretch films, plastic bags, plastic wrap, tapes, etc.

● Printing industry : Functional polyester film can be used to make printing substrates, and its flatness and surface finish can make the printing effect clearer and finer. At the same time, its high strength, wear resistance, chemical corrosion resistance and other characteristics can also make printing materials have good durability.

● Solar cell industry : Functional polyester film can be used in the field of solar cells. Due to its UV resistance, high temperature resistance, weather resistance and other characteristics, it can be used to protect the surface of solar panels and improve the life and efficiency of solar panels.

- Medical industry : Functional polyester films also have certain applications in the medical industry. For example, it can be used in medical dressings, surgical packaging, etc. Its high strength, high transparency and chemical resistance can ensure the quality and safety of medical products.

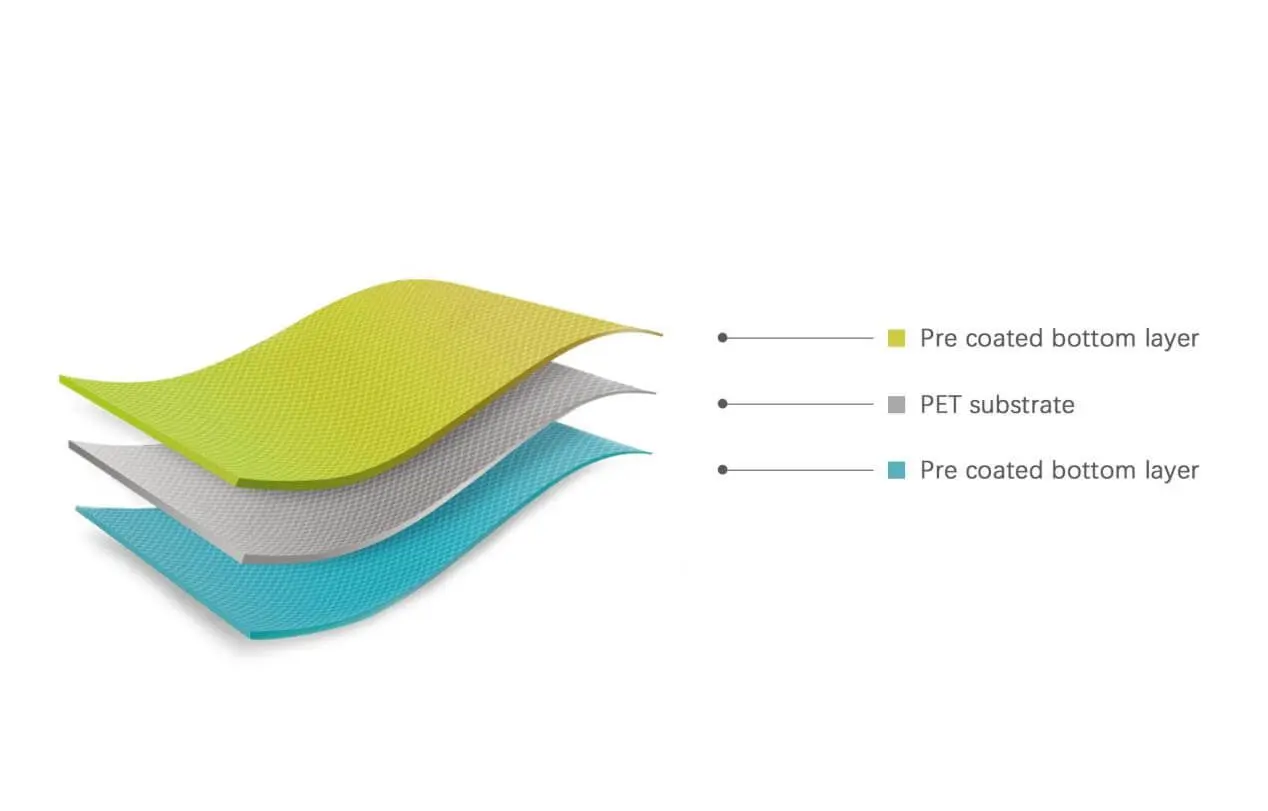

- Optical field: Optical films are mainly used in diffusion films, brightness enhancement films, reflective films, antistatic protective films in high-end LCD equipment, protective films in touch screens, and films for soft displays. Among the upstream raw materials for LCD panels, optical films are used in backlight modules, polarizers, and liquid crystal materials. For example, an LCD display can use at least 7 to 8 PET optical films with different functions (2 light diffusion films, 1 brightness enhancement film, 2 phase difference films, 1 anti-glare film, and 1 shielding conductive film) . These functional PET optical films are mainly obtained by coating various functional coatings on the surface of PET polyester films.