Trustworthy brand, over twenty years of experience

In the rapidly developing automobile industry, people are constantly pursuing lighter and better performing cars. Traditional glass materials can no longer meet manufacturing needs. Many manufacturers are beginning to look for new materials to replace glass.

After learning about the plight of these manufacturers, Kaixin’s engineers began to try new materials. We have helped many auto parts manufacturers in China solve their problems. Our materials have also been extensively validated. We plan to promote our products globally so that manufacturers around the world can enjoy low cost and efficient solutions.

We Offer Three Main Materials

PC film is widely used in the automotive field. Its high transparency, heat resistance, light resistance, chemical stability and mechanical strength allow it to be made into a variety of different parts, thereby improving the performance and performance of the car exterior. The following introduces some applications of polycarbonate PC films in the automotive field.

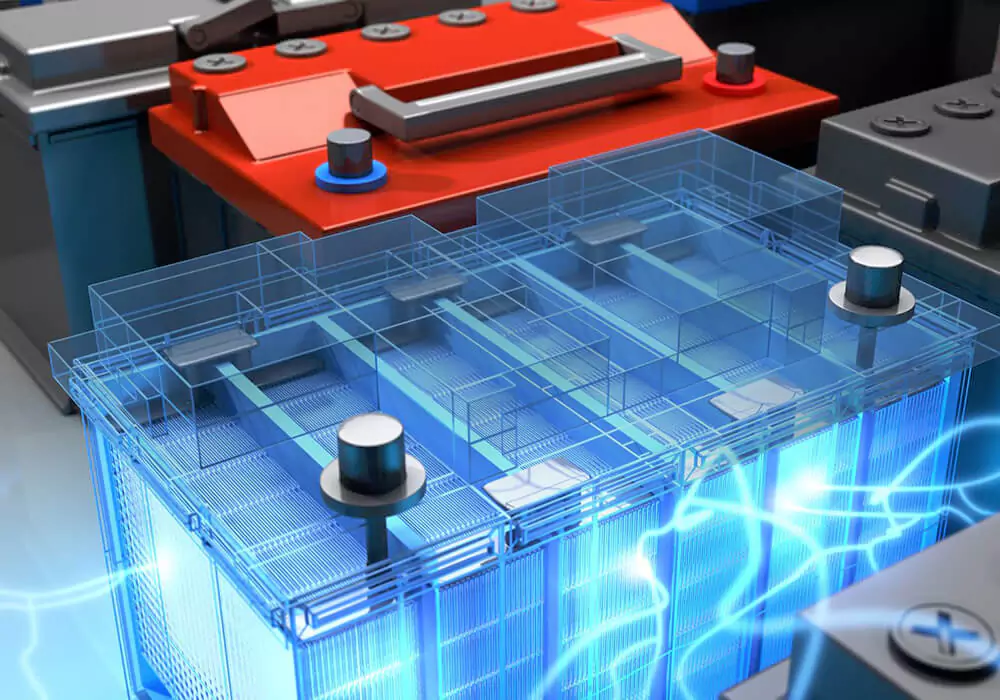

- New energy vehicles: Flame retardant PC film has good insulation and flame retardant properties and can be used in outdoor charging piles and power battery systems of new energy vehicles.

- Vehicle display panel: PC film is an optical plastic with excellent performance and has a wide range of application scenarios in the field of vehicle display screens. From central control displays, electronic instrument panels to HUD heads-up displays, more and more screens are installed in smart cars, bringing a better experience to people’s travels.

- Automobile headlights: PC film has high transparency and excellent heat resistance, so it is often used to make car headlights, taillights, turn signals and other headlight covers.

- Car dashboard: PC film has good surface flatness and rigidity and can be used to make interior parts such as car dashboards and storage box covers.

- Car body decoration: PC film can be produced in various patterns and colors, so it can be used in car body decoration, such as car body wraps, car body advertising, etc.

- Automotive glass: PC film can be made into high-transparency polycarbonate sheets, and can also be used as covering film for automotive glass to improve the wear resistance of automotive glass.

- Vehicle display panel: PC and PMMA composite film is an optical plastic with excellent performance and has a wide range of application scenarios in the field of vehicle display screens. Compared with PC film, it has better surface hardness and better molding ability. Such a display cover is more resistant to high temperatures, scratches, and oil stains.

- Automotive interior IMD/IML:PC and PMMA composite film has good impact resistance and scratch resistance. For decorative and infrequently touched parts, choose PC and PMMA film, which has a higher cost performance. For frequently touched parts, choose PC and PMMA+ hardened diaphragm which has relatively excellent resistance to scratches and chemical media.

- The ultra-thin 100-micron acrylic film has the characteristics of acrylic resin such as excellent transparency, weather resistance, thermoforming and composite processability. It also has the ability to cut off ultraviolet rays and can be used in the INS process to make automotive interiors.

Here is a brief summary of the application of PMMA and composite boards in vehicle displays

| Compare performance | Casting method PMMA board | PC and PMMA composite board | Optical PC injection molding |

| Transmittance | ★★★★★ | ★★★★ | ★★★ |

| Impact resistance | ★★★ | ★★★★ | ★★★★★ |

| Surface hardness | Can be hardened for more than 4H | Can be hardened for more than 4H | 2H after hardening |

| Temperature resistance | -40~+110℃ | ★★★★ | -45~+135℃ |

| rainbow pattern | / | / | Reduced by injection molding process |

| 3D molding equipment | Air high pressure machine | Air high pressure machine | Electric injection molding machine, air high pressure machine, etc. |

| Assembly structure | none | none | Injection molding |