Special Functional Optical Clear Adhesive (OCA)

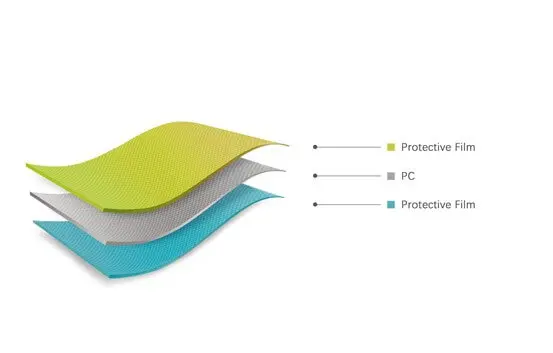

Textured Polycarbonate Film

Description

Kaixin optical grade polycarbonate (PC) film is light and thin, ultra-transparent and clear, excellent printing ability and optical properties. Its light transmittance can reach more than 91%, and the transmittance in the ultraviolet band is very low. The crystal points and concave and convex points are strictly controlled to eliminate impurities, foreign matter, scratches and other defects. It has built-in insulation properties and is an ideal hardening and plating material. At the same time, its physical properties are also extremely excellent, showing excellent impact resistance, scratch resistance, heat resistance and weather resistance. Optical-grade PC films have stable physical properties and can operate in harsh environments, so they are widely used.

The manufacturing process and performance requirements of optical grade PC films are very high. In the manufacturing process, advanced stretching technology is used. By continuously stretching the PC material, its crystal lattice is ordered, making it more transparent, optically better, and more stable than ordinary PC films. In terms of physical properties, PC materials need to be upgraded and improved to have higher heat distortion temperature and strength.

For the field of graphics and text printing, Kaixin film performance characteristics: excellent weather resistance, temperature resistance and excellent impact strength, strong pattern adhesion, diverse colors, good flexibility, never fade, and good wear resistance. It has wide applicability, long service life, easy processing, strong temperature adaptability, and has a variety of standards and performance levels to choose from in different application fields.

Features

- High transparency: Polycarbonate (PC) film has high transparency, with a transmittance of more than 90%. It is an excellent light-transmitting material and can be used to manufacture optical devices, liquid crystal displays, etc.

- Good mechanical properties: Polycarbonate (PC) film has excellent mechanical properties such as high strength, high rigidity, wear resistance, and impact resistance. It can be used to manufacture various products that require high strength and high toughness, such as mobile phone casings, car lampshades, Safety glass etc.

- High temperature resistance and flame retardant properties: Polycarbonate (PC) film is resistant to high temperatures, generally 120-140°C. There are also special polycarbonate materials that can withstand temperatures above 160°C. The material is widely used in automobiles, electronics, aerospace and other fields.

- Corrosion resistance: Polycarbonate (PC) film has good corrosion resistance to most chemicals and can maintain the stability of its performance and appearance.

Applications

- In-mold decoration applications for automotive interiors, appliances and consumer electronics.

- Window/LCD display window, panel.

- Display light guide panel.

- Optical instrument eyepieces, protective glass.

- Automobile dashboard, aviation glass, etc.

- Washing machine panel label.

Technical Data Sheet

| Typical physical properties | |||

| Properties | Value | Unit | Test Method |

| Physical properties | |||

| Density | 1.2 | g/cm3 | ISO 1183 |

| Haze | <0.5 | % | ASTM D1003 |

| Transmittance | 91 | % | ASTM D1003 |

| Mechanical properties | |||

| Tensile Strength | 60 | Mpa | ISO 527 |

| Elongation at break | ˃100 | % | ISO 527 |

| Tensile modulus | 2300 | Mpa | ISO 178 |

| Bending strength | 91 | Mpa | ISO 178 |

| Surface Tension | ≥34 | dyn/cm | Testing liquid |

| Electrical properties | |||

| Dielectric constant | 3 | — | IEC 60250 |

| Withstand voltage value | 30 | KV/mm | IEC 60243 |

| Arc resistance | 250 | — | IEC 60112 |

| Surface resistivity | 1.00E+16 | Ω/square | IEC 60093 |

| Volume resistivity | 1.00E+17 | Ω/cm | IEC 60093 |

| Thermal properties | |||

| Thermal expansion coefficient | 5.8 | x10-5/℃ | ISO 11359 |

| Thermal conductivity | 0.2 | W/(m*K) | ASTM D5470 |

| Shrinkage (150℃) | 0.5∽0.7 | % | ASTM D1204 |

| Glass transition temperature | 152 | ℃ | ISO 306 |

| Flammability | |||

| Flammability rating | V-2/VTM-2 | E 249605 | |

| Note: This test is for reference only and is not an absolute application indicator. | |||