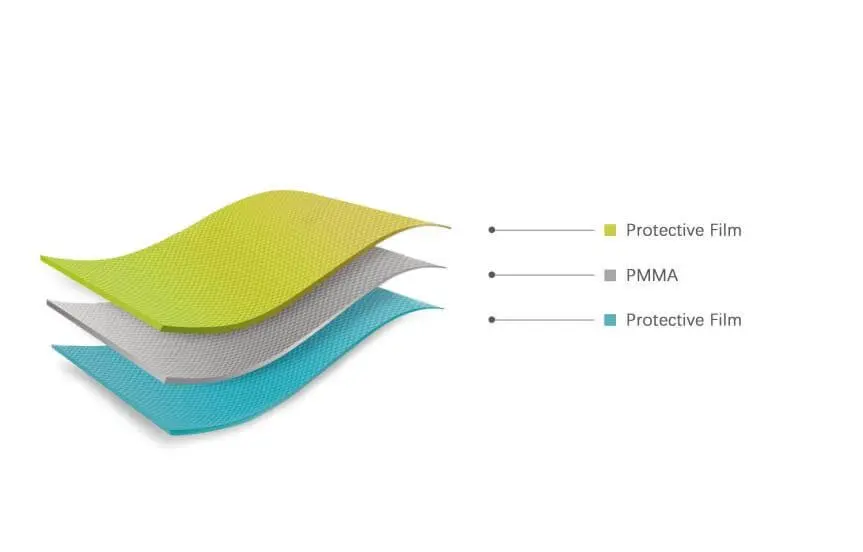

Composite Material

Description

Acrylic, also called PMMA or organic glass , comes from the English acrylic (acrylic plastic), and its chemical name is polymethyl methacrylate . It is an important plastic polymer material developed earlier. It has good transparency , chemical stability and weather resistance , easy to dye, process. Widely used in the construction industry. Plexiglas products can generally be divided into cast sheets, extruded sheets and molding compounds .

Acrylic film (PMMA for short) has excellent transparency, weather resistance, thermoforming and composite processability, and also has the ability to cut off ultraviolet rays. The applications are very wide and are not limited to aesthetics, but also include optics, protection, lighting and multiple industrial fields. Its high transparency, wear resistance and engineering properties make it one of the materials of choice for many applications.

Features

- Excellent weather resistance, low moisture transmission and high light transmission, low photo-elastic coefficient, good processing performance, non-toxic and excellent comprehensive performance.

- Good processing adaptability, both thermoforming and mechanical processing can be used.

- Can be printed, colored, and pasted, with long-term color and gloss stability under outdoor exposure, and excellent UV resistance.

- Printable.

Applications

- Flat-panel displays and liquid crystal displays (LCD): Acrylic film (PMMA) is widely used in the outer protective layer of flat-panel TVs, computer monitors and LCD screens. It has high transparency, wear resistance and scratch resistance, which can effectively protect the display and provide a clear visual experience.

- Lighting applications: Acrylic film (PMMA) can be used for lighting coverings, such as LED lampshades and street lamp coverings. It diffuses light and improves the uniformity and softness of lighting.

- Solar panels: Acrylic film (PMMA) can be used as a covering for solar panels, protecting the batteries and ensuring that light can pass through to generate electricity.

- Automotive field: In cars and other vehicles, acrylic film (PMMA) can be used for car windows, front windshields and car light covers. Its lightweight and high-strength properties make it ideal for use in the automotive sector. At the same time, ultra-thin 100 micron acrylic can also be used in the INS process of automotive interiors.

- Medical equipment: Acrylic film (PMMA) can be used to manufacture medical equipment, such as surgical instruments, ward doors and windows, medical device shells, etc. Its highly transparent properties are valuable for medical applications.

- Decoration and architecture: Acrylic film (PMMA) can be used in architectural glass, decorative materials and art production to improve appearance, provide protection and increase design creativity.

- Electronic equipment: In electronic equipment, acrylic film (PMMA) can be used to manufacture touch screens, panel indicators, buttons and displays to provide protection and visual effects.

- Reflective material: Due to its superior weather resistance and color-ability, it is used as a surface film for high-brightness reflective sheets for traffic signs. In addition, in order to maintain bright colors, it is also used as a cover layer for ink-jet printing on outdoor signage.

Difference between optical grade PMMA and regular grade PMMA

The polymers obtained by polymerizing general-grade acrylic with acrylic acid and its esters are collectively called acrylic resins, and the corresponding plastics are collectively called poly-acrylic plastics, among which poly-methyl methacrylate is the most widely used. The abbreviation code of polymethylmethacrylate is PMMA, commonly known as plexiglass. It is by far the most excellent synthetic transparent material and the price is relatively affordable.

Application: PMMA is soluble in organic solvents, such as phenol, anisole, etc., and can form a good film through spin coating. It has good dielectric properties and can be used as an organic field effect transistor (OFET), also known as an organic thin film transistor (OTFT). The difference between optical grade PMMA and ordinary grade acrylic is that the light transmittance is higher. Optical grade PMMA has a higher light transmittance and better transparency. Ordinary acrylic has a light transmittance of 92%, and high-transparent acrylic can reach 93%. Used to make LED lenses, car lights, lens products, and light guide plates.

Ordinary-grade acrylic has crystal-like transparency, with a light transmittance of more than 92%. Acrylic (acrylic) colored with dyes has a good color development effect. In addition, acrylic sheets (acrylic sheets) have excellent Weather resistance, higher surface hardness and surface gloss and better high temperature performance. In addition, acrylic sheets can be laser cut and engraved to produce products with unique effects. Optical grade acrylic film (PMMA) has a transparent light rate comparable to that of glass, but its density is only half that of glass. In addition, it is not as fragile as glass, and even if it is broken, it will not form sharp fragments like glass. The wear resistance of acrylic sheets is close to that of aluminum, and it is resistant to corrosion by a variety of chemicals from time to time. Acrylic sheets are printable and excellent spraying performance. Appropriate printing (such as screen printing) and spraying processes can be used to give acrylic products (acrylic products) ideal surface decoration effects. Specially modified optical-grade acrylic films (referred to as PMMA) can absorb a large amount of ultraviolet light. In addition, smoldering acrylic (acrylic) can still help overcome fire hazards in specific places. The impact strength of high-impact acrylic is 6 to 10 times that of acrylic, and the surface has been specially treated. The ultra-wear-resistant acrylic board can withstand extremely harsh tests.

Technical Data Sheet : Acrylic film

| Typical physical properties | |||

| Properties | Value | Unit | Test Method |

| Physical properties | |||

| Water absorption | 0.3 | % | GB/T 1034 |

| Density | 1.19 | g/cm³ | GB/T 1033 |

| Hzae | <1 | % | GB/T 2410 |

| Transmittance | ≥91 | % | GB/T 2410 |

| Mechanical properties | |||

| Tensile Strength | 74 | Mpa | GB/T 1040 |

| Elongation at break | 6 | % | GB/T 1040 |

| Bending strength | 125 | Mpa | GB/T 9341 |

| Hardness | HB | H | Mitsubishi pencil 750g; GB/T 6739 |

| Electrical properties | |||

| Surface resistivity | >1E16 | Ω-cm | GB/T 1040 |

| Volume resistivity | >1E16 | Ω-cm | GB/T 1040 |

| Arc resistance | / | / | GB/T 1411 |

| Thermal properties | |||

| Thermal expansion coefficient | 7*10 E-5 | 1/℃ | GB/T 1636 |

| Specific heat | 1.5 | j/g-℃ | / |

| Heat distortion temperature | 96 | ℃ | GB/T 1634 |

| Thermal conductivity | 0.21 | W/(M-K) | GB/T 3399 |

| Note: This test is for reference only and is not an absolute application indicator. | |||