Description

In the application of housing materials for contemporary electronic products, if we say which material is used the most, polycarbonate is undoubtedly the “king of engineering plastics”. Its English name is Polycarbonate , which has particularly good impact resistance, thermal stability, and gloss, inhibit bacteria and resist pollution, and have a wide operating temperature range (-60~120℃) .

Our polycarbonate film products are used in automotive products, membrane switches, lighting applications, anti-fog/anti-glare and other functional products, LED/LCD displays, electronic circuit boards, ID cards, etc. Kaixin’s unique portfolio of high-performance plastic films helps meet customers’ changing application specifications. All our film products are RoHS and REACH certified and comply with environmental protection requirements. Kaixin’s polycarbonate film products provide high-performance, high-quality engineering thermoplastic films/sheets for a variety of industries.

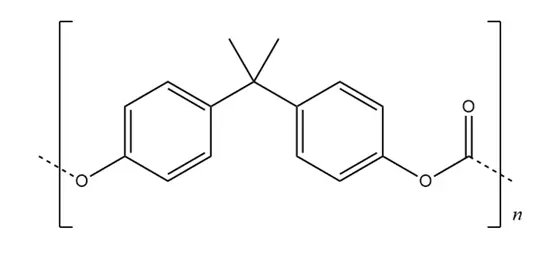

Structure

Polycarbonate (PC) is the general name for polymer compounds containing carbonate in the main chain of the molecule. Polycarbonate with a linear structure of dihydroxy compounds is generally represented by the following general formula:

Polycarbonate (PC) is a polyester of carbonic acid. Carbonic acid itself is not stable, but its derivatives (such as phosgene , urea , carbonates , and carbonates ) have certain stability. Although the melting temperature of aliphatic-aromatic polycarbonate is higher than that of aliphatic polycarbonate, it has little practical value due to its large crystallization tendency, brittleness, and poor mechanical strength. What is really of practical value is aromatic polycarbonate. Considering the low price of raw materials, product performance and processing performance, only bisphenol A aromatic polycarbonate can be industrially produced. Bisphenol A polycarbonate is obtained by reacting bisphenol A with phosgene (phosgene) or transesterification with diphenyl carbonate. Because the molecule contains strong polar carbonyl and dioxy bonds (-O-R-O-), the intermolecular force is strong, and it is an amorphous thermoplastic engineering plastic with excellent mechanical properties and heat resistance.

Features

Polycarbonate has outstanding impact toughness, transparency and dimensional stability, excellent mechanical properties, electrical insulation, wide operating temperature range, good creep resistance, weather resistance, low water absorption, non-toxicity, and is self-contained. It is an engineering plastic with excellent comprehensive properties.

-Physical and chemical properties: Pure polycarbonate resin is an amorphous, tasteless, odorless, non-toxic and transparent thermoplastic polymer. The relative molecular mass is generally in the range of 2000~7000, the relative density is 1.18~1.20, and the glass transition The temperature is 140~150℃, and the melting range is 220~230℃.

– Chemical corrosion resistance: At normal temperature, it will not dissolve or cause performance changes under the long-term action of the following chemical reagents: 20% hydrochloric acid, 20% sulfuric acid, 20% nitric acid, 40% hydrofluoric acid, 10% ~ 100% formic acid , 20% ~ 100% acetic acid, 10% sodium carbonate aqueous solution, saline solution, 10% potassium dichromate + 10% sulfuric acid compound solution, saturated potassium bromide aqueous solution, 30% hydrogen peroxide, aliphatic hydrocarbons, animal and vegetable oils, lactic acid, oleic acid , soap and most alcohols. However, formic acid and acetic acid are slightly corrosive.

– Excellent oil resistance: When soaked in natural gasoline for 3 months or in lubricating oil at 125°C for 3 months, the size and quality of the product will remain basically unchanged. Of course, after being soaked in high-volatile gasoline at room temperature for 1 month, its surface will be slightly corroded.

Applications

For polycarbonate film

Uncoated Film

Coated Film